des . 24, 2024 00:55 Back to list

air breather filter

Understanding Air Breather Filters Importance and Functionality

Air breather filters are essential components used across various applications, primarily to ensure that the air entering a system remains clean and free from contaminants. Whether in industrial machinery, automotive engines, or even household appliances, these filters play a crucial role in maintaining the efficiency and longevity of the equipment they protect.

The Functionality of Air Breather Filters

The primary function of an air breather filter is to provide a barrier against dirt, dust, and other airborne particles that could harm the internal components of a machine. Air breather filters allow clean air to enter while preventing unwanted particulates from entering a system. This is particularly important in environments where machinery operates under strenuous conditions, which can lead to the accumulation of dirt and debris.

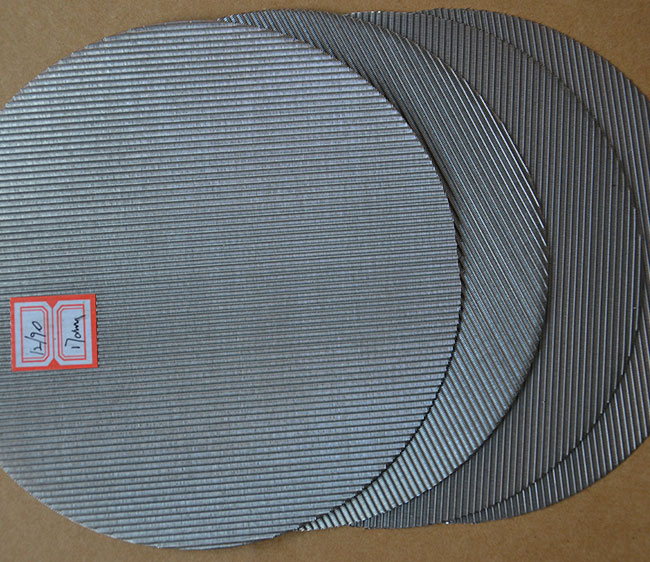

These filters typically consist of a porous medium that allows air to pass while trapping contaminants. Depending on the application, the design and materials used in air breather filters can vary significantly. For instance, some may use paper or synthetic fibers, while others might utilize foam or mesh materials designed to optimize filtration efficiency.

Types of Air Breather Filters

Air breather filters come in various forms, tailored to specific applications

. Here are a few common types1. Engine Air Filters Used primarily in automobiles, these filters clean the air entering the engine for combustion. A clean air filter promotes better fuel efficiency, increases engine performance, and reduces emissions.

2. Hydraulic Oil Breathers Found in hydraulic systems, these breather filters allow the safe venting of air while filtering out contaminants that could otherwise contaminate the hydraulic fluid.

3. Industrial Equipment Filters These filters are used in heavy machinery and industrial equipment to protect sensitive components from dust and other particles, thereby extending the equipment’s lifespan.

air breather filter

4. Fuel Breathers These filters serve in fuel tanks and lines, allowing pressure equalization while ensuring that no contaminants enter the fuel system.

Importance of Regular Maintenance

One crucial aspect of air breather filters is the need for regular maintenance. Over time, these filters can become clogged with dirt and debris, reducing their efficiency and allowing harmful particles to enter the system. Regular inspection and timely replacement of air breather filters not only ensure optimal performance but also help in preventing costly repairs and downtime.

For example, in automotive engines, a clogged air filter can lead to reduced engine performance, decreased fuel efficiency, and increased emissions. General recommendations suggest replacing engine air filters every 15,000 to 30,000 miles, depending on the driving conditions and vehicle usage. Similarly, industrial air filters may need to be changed based on the level of contamination in the environment they operate within.

Advancements in Air Filter Technology

As industries evolve, so does technology surrounding air breather filters. Innovations in materials and design have led to the development of more efficient filters capable of capturing smaller particles and providing higher airflow rates. For instance, some modern filters utilize nanofiber technology, which allows for superior filtration while maintaining lower pressure drops.

Additionally, manufacturers have started focusing on sustainable practices by developing filters made from recyclable materials. This not only addresses environmental concerns but also appeals to the growing market of eco-conscious consumers.

Conclusion

Air breather filters are fundamental to various mechanical systems, serving as the first line of defense against airborne contaminants that can compromise efficiency and functionality. From automotive engines to industrial machinery, maintaining clean air is paramount for optimal performance. Regular maintenance and leveraging advancements in filter technology can lead to significant benefits, including enhanced efficiency, reduced operational costs, and a longer lifespan for machinery. As we continue to innovate in the realm of air filtration, air breather filters will remain a vital component in preserving the integrity and efficiency of modern technological systems.

share

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025