des . 25, 2024 12:19 Back to list

best stainless steel wire mesh for screen printing

The Best Stainless Steel Wire Mesh for Screen Printing

Screen printing is a popular and versatile method used for a variety of applications, from textile printing to graphic designs on various surfaces. One critical component that significantly influences the quality and efficiency of the screen printing process is the type of wire mesh used. Among the available options, stainless steel wire mesh stands out due to its durability, strength, and resistance to corrosion. This article explores the best stainless steel wire mesh options for screen printing, delving into factors like mesh count, wire diameter, and application suitability.

Understanding Stainless Steel Wire Mesh

Stainless steel wire mesh is made from a blend of stainless steel alloys, making it both resilient to environmental factors and structurally robust. This type of mesh can withstand high tension, reducing the likelihood of deformation during the printing process. Its non-corrosive properties enhance its longevity, making it an ideal choice for industries looking for reliable and consistent performance.

Key Features of Stainless Steel Wire Mesh

1. Durability Stainless steel wire mesh is known for its resistance to wear and tear. Unlike other materials, it does not degrade easily over time, even under challenging printing conditions. This durability translates to extended use and fewer replacements, thereby proving to be cost-effective in the long run.

2. Screen Detail Retention The ability of stainless steel mesh to maintain fine details is crucial for achieving high-quality prints. The tight weave and precise openings of a good stainless steel mesh allow for the intricate details of designs to come through sharply, ensuring that every print meets the desired quality standards.

3. Resistant to Chemicals In screen printing, various inks and chemicals are often used. Stainless steel wire mesh exhibits a high level of resistance to these substances, reducing the chances of degradation and ensuring longevity. This is particularly important for printers working with solvent-based inks or other aggressive substances.

4. Thermal Stability Stainless steel wire mesh can withstand high temperatures without losing its structural integrity. This feature is beneficial for screen printing processes that involve curing inks, as it prevents warping and enhances the quality of the final product.

Choosing the Right Mesh Count and Wire Diameter

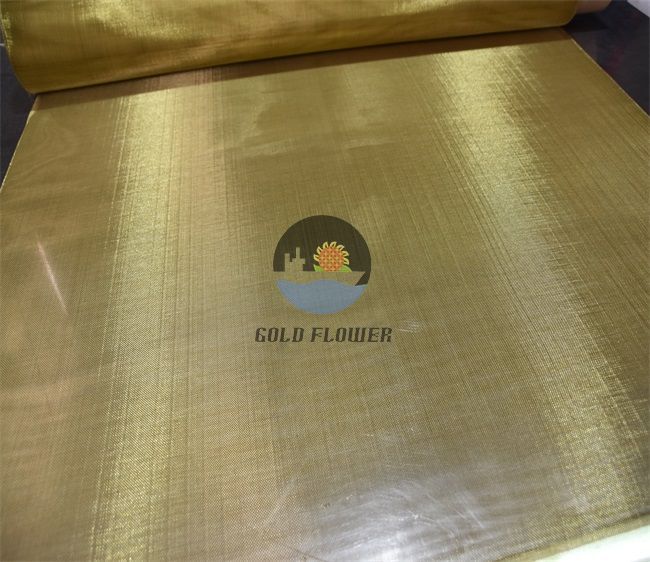

best stainless steel wire mesh for screen printing

When selecting stainless steel wire mesh for screen printing, two critical factors must be considered mesh count and wire diameter.

- Mesh Count This refers to the number of threads per inch, both horizontally and vertically. A higher mesh count results in finer screens that can produce detailed images, while a lower count is better suited for thicker inks and bold designs. The typical range for screen printing might be between 35 to 400 mesh, depending on the specific requirements of the project.

- Wire Diameter The diameter of the wire used in the mesh also affects the printing outcome. Thicker wires provide more strength but may reduce the level of detail produced, while thinner wires allow for sharper prints but can be less durable. For optimal results, a balance between mesh count and wire diameter should be achieved based on the type of ink and substrate used.

Recommendations for Best Stainless Steel Wire Mesh

1. Tensioned Stainless Steel Mesh These are pre-stretched and tensioned for optimal performance. They are recommended for high-speed printing and can significantly improve registration accuracy.

2. MicroDot Mesh This type features a unique dot pattern that allows for excellent ink flow while maintaining high-resolution printing. It is ideal for detailed artwork and printing on challenging fabrics.

3. Wide Mesh Options For applications requiring a thicker ink deposit, wide mesh options (such as 50-80 mesh) are recommended. They allow for easier ink transfer while maintaining quality.

Conclusion

Selecting the right stainless steel wire mesh for screen printing is paramount for achieving high-quality prints. With options ranging from high-tensioned meshes for precision to wider weaves for thicker inks, understanding your specific printing needs is key. By investing in the best stainless steel wire mesh, screen printers can not only enhance the quality of their prints but also ensure a longer lifespan and efficiency in their printing processes. As the industry evolves, the adaptability and superior performance of stainless steel mesh will continue to make it a top choice for professionals in the field.

share

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025