feb . 11, 2025 00:03 Back to list

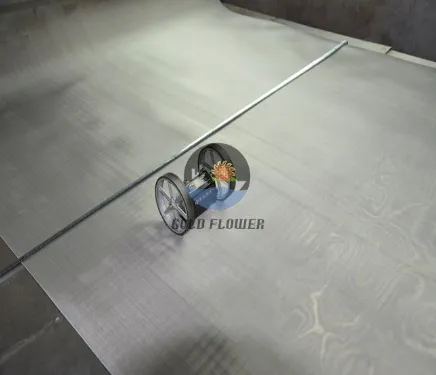

Woven Wire Drapery

Choosing the right fine stainless steel mesh for your project can significantly impact the efficiency and effectiveness of your application. As someone with a wealth of experience in the field of materials and engineering, I aim to provide you with an authoritative and trustworthy guide that outlines the key considerations and finer details in selecting stainless steel mesh that suits your needs.

In my extensive professional experience, I have seen cases where the inappropriate selection of stainless steel mesh led to increased operational costs and downtime. For instance, selecting a mesh with inadequate corrosion resistance in a coastal environment can result in rapid degradation and frequent replacements. Conversely, choosing too high a grade, unnecessarily, can inflate project costs without added benefits. Understanding the environment and specific needs of your application is crucial in making an informed decision. Another factor to consider is the supplier's credibility. Experienced suppliers offer a detailed material specification and support you in choosing the right product for your application. This trust between the supplier and buyer is foundational in ensuring that the mesh you purchase is of high quality, adheres to industry standards, and is fit for purpose. Economic considerations also play a role. While initial costs are essential, assess the long-term cost benefits, especially when considering maintenance and replacement frequencies. A slightly higher upfront investment in a quality product like superior grade stainless steel mesh can lead to significant savings and operational efficiency over time. In conclusion, purchasing fine stainless steel mesh requires a blend of technical knowledge, practical experience, and market awareness. With a clear understanding of your specific application needs and by engaging reliable suppliers, you can ensure you are making an informed, expert decision. This strategic approach not only optimizes performance but also maximizes value, ensuring the investment stands the test of time.

In my extensive professional experience, I have seen cases where the inappropriate selection of stainless steel mesh led to increased operational costs and downtime. For instance, selecting a mesh with inadequate corrosion resistance in a coastal environment can result in rapid degradation and frequent replacements. Conversely, choosing too high a grade, unnecessarily, can inflate project costs without added benefits. Understanding the environment and specific needs of your application is crucial in making an informed decision. Another factor to consider is the supplier's credibility. Experienced suppliers offer a detailed material specification and support you in choosing the right product for your application. This trust between the supplier and buyer is foundational in ensuring that the mesh you purchase is of high quality, adheres to industry standards, and is fit for purpose. Economic considerations also play a role. While initial costs are essential, assess the long-term cost benefits, especially when considering maintenance and replacement frequencies. A slightly higher upfront investment in a quality product like superior grade stainless steel mesh can lead to significant savings and operational efficiency over time. In conclusion, purchasing fine stainless steel mesh requires a blend of technical knowledge, practical experience, and market awareness. With a clear understanding of your specific application needs and by engaging reliable suppliers, you can ensure you are making an informed, expert decision. This strategic approach not only optimizes performance but also maximizes value, ensuring the investment stands the test of time.

share

Next:

Latest news

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025