feb . 16, 2025 02:17 Back to list

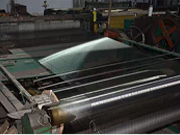

Woven Wire Drapery

When considering the purchase of a steel wire mesh machine, it's crucial to delve into specifics to make an informed decision that balances cost, efficiency, and quality. Understanding the core functionalities, applications, and technological advancements in these machines can guide you towards the best choice for your manufacturing needs.

Recent technological advancements have introduced smart machinery capable of integrating with existing systems for data collection and performance monitoring. The advent of IoT (Internet of Things) has enabled real-time data analysis, predictive maintenance, and remote diagnostics. Such features not only enhance productivity but also extend equipment longevity through proactive maintenance protocols. Energy efficiency is emerging as a significant factor in machinery selection, driven by environmental considerations and cost-saving imperatives. Modern steel wire mesh machines are increasingly equipped with energy-efficient motors and components that reduce electricity consumption without sacrificing production capabilities. Opting for machinery with high energy efficiency ratings can lead to substantial savings over time and aligns with sustainable manufacturing practices. The credibility of manufacturers is another critical element influencing purchase decisions. Reputable manufacturers offer robust warranties and customer support services, which can be vital for troubleshooting and maintenance. Investigating the company's track record in producing durable and reliable equipment provides assurance of your investment’s longevity and performance sustainability. For hands-on operators and businesses new to wire mesh production, seeking professional consultations or engaging with industry experts can be invaluable. These consultations can provide tailored advice based on specific project needs and budgetary constraints. Furthermore, exploring demonstrations or trial periods can offer first-hand experience of a machine's operation, allowing for a practical assessment of its suitability for your needs. In conclusion, acquiring a steel wire mesh machine is a multifaceted decision that requires a thorough analysis of your production needs, technological preferences, and financial considerations. By investing time in understanding the capabilities and innovations within these machines, businesses can significantly enhance their operational efficiency while maintaining high standards of quality and sustainability. Whether for large-scale industrial applications or smaller bespoke projects, the right steel wire mesh machine serves as a cornerstone in achieving production excellence.

Recent technological advancements have introduced smart machinery capable of integrating with existing systems for data collection and performance monitoring. The advent of IoT (Internet of Things) has enabled real-time data analysis, predictive maintenance, and remote diagnostics. Such features not only enhance productivity but also extend equipment longevity through proactive maintenance protocols. Energy efficiency is emerging as a significant factor in machinery selection, driven by environmental considerations and cost-saving imperatives. Modern steel wire mesh machines are increasingly equipped with energy-efficient motors and components that reduce electricity consumption without sacrificing production capabilities. Opting for machinery with high energy efficiency ratings can lead to substantial savings over time and aligns with sustainable manufacturing practices. The credibility of manufacturers is another critical element influencing purchase decisions. Reputable manufacturers offer robust warranties and customer support services, which can be vital for troubleshooting and maintenance. Investigating the company's track record in producing durable and reliable equipment provides assurance of your investment’s longevity and performance sustainability. For hands-on operators and businesses new to wire mesh production, seeking professional consultations or engaging with industry experts can be invaluable. These consultations can provide tailored advice based on specific project needs and budgetary constraints. Furthermore, exploring demonstrations or trial periods can offer first-hand experience of a machine's operation, allowing for a practical assessment of its suitability for your needs. In conclusion, acquiring a steel wire mesh machine is a multifaceted decision that requires a thorough analysis of your production needs, technological preferences, and financial considerations. By investing time in understanding the capabilities and innovations within these machines, businesses can significantly enhance their operational efficiency while maintaining high standards of quality and sustainability. Whether for large-scale industrial applications or smaller bespoke projects, the right steel wire mesh machine serves as a cornerstone in achieving production excellence.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025