nóv . 14, 2024 09:36 Back to list

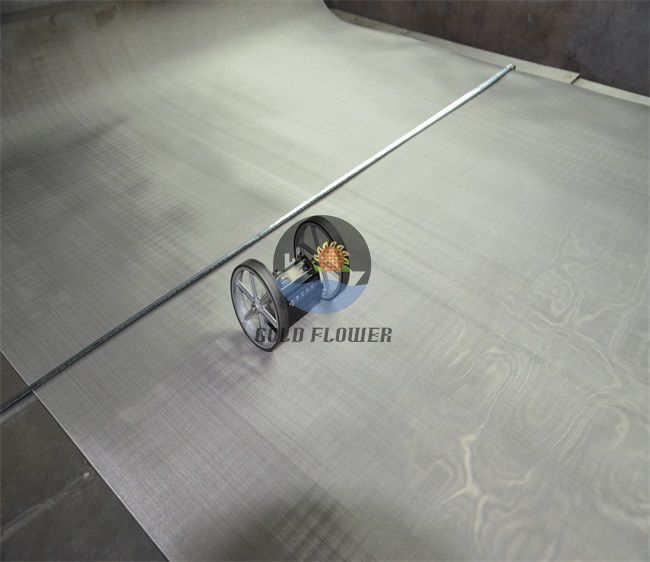

famous high temperature mesh

Understanding High-Temperature Mesh Materials An Overview

High-temperature mesh materials have become increasingly significant in various industries due to their unique properties and capabilities. These materials, often made from metals, ceramics, or composite fibers, are engineered to withstand extreme thermal conditions while maintaining structural integrity and functionality. This article delves into the characteristics, applications, and advancements in high-temperature mesh technologies.

Characteristics of High-Temperature Mesh Materials

High-temperature mesh materials are primarily defined by their ability to endure high operational temperatures, often exceeding 1000 degrees Celsius (1832 degrees Fahrenheit). These materials exhibit several key properties that set them apart from traditional mesh options

1. Thermal Resistance The most notable characteristic of high-temperature meshes is their thermal resistance. This property is critical in environments such as furnaces, reactors, and metal processing facilities, where materials are often subjected to intense heat.

2. Mechanical Strength In addition to thermal resistance, these meshes are designed to maintain structural strength under heavy loads and adverse conditions. The combination of high tensile strength and flexibility allows them to be used in dynamic applications without risking failure.

3. Corrosion Resistance High-temperature environments often expose materials to corrosive substances. High-temperature meshes are treated or composed of materials that resist oxidation and corrosion, ensuring longevity and reliability.

4. Chemical Stability Many high-temperature meshes are chemically stable, which is vital for applications in corrosive atmospheres or reactive environments. This stability prevents degradation that can compromise safety and efficiency.

5. Lightweight Despite their robustness, many high-temperature meshes are designed to be lightweight, aiding in their versatility across various applications.

Applications of High-Temperature Mesh Materials

The unique properties of high-temperature mesh materials make them suitable for a broad range of applications across multiple industries

1. Aerospace In the aerospace sector, high-temperature meshes are used in thermal protection systems, insulation, and combustion components. These materials help to manage extreme temperatures during flight and re-entry.

famous high temperature mesh

2. Automotive High-temperature meshes find use in automotive exhaust systems, turbocharger components, and heat shields. Their ability to withstand high temperatures and prevent thermal damage enhances vehicle performance and safety.

3. Forging and Metal Processing Industries involved in forging, welding, and other high-heat metal processing applications rely on high-temperature meshes for filtration, support structures, and protective barriers, ensuring efficient operations without compromising integrity.

4. Energy Production High-temperature meshes are essential in power generation, particularly in gas turbines, where they are used in filtration systems and heat exchange components.

5. Chemical Processing In the chemical industry, these meshes serve as durable filtration media and separation tools in reactors and distillation columns, facilitating efficient chemical reactions at high temperatures.

Advancements in High-Temperature Mesh Technology

Innovation in materials science has led to significant advancements in high-temperature mesh technologies. Research is ongoing to develop new alloys, composites, and coatings that enhance the performance of these materials. Some notable trends include

1. Nanotechnology The incorporation of nanoparticles into mesh structures is being explored to improve thermal and mechanical properties. This advancement can lead to even higher performance materials that outperform traditional options.

2. 3D Printing Additive manufacturing technologies are being used to create complex mesh structures that are lightweight yet incredibly strong. This method allows for customization and optimization for specific applications.

3. Smart Materials The development of smart high-temperature meshes embedded with sensors offers potential for real-time monitoring of temperature and structural integrity, enhancing safety and operational efficiency.

Conclusion

High-temperature mesh materials are becoming indispensable in various high-performance industries. Their unique blend of thermal resistance, mechanical strength, and corrosion resistance allows for a safer and more efficient operation in extreme conditions. As technology advances, the ongoing development of these materials promises to expand their applications and improve their reliability, ensuring that they remain at the forefront of material science and engineering. The future of high-temperature meshes looks bright, paving the way for innovations that will continue to drive industry standards and practices forward.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025