okt . 12, 2024 18:07 Back to list

odm wire mesh the range

Understanding ODM Wire Mesh A Comprehensive Overview

Wire mesh is an essential material in a variety of industries, including construction, manufacturing, and agriculture. Within this domain, ODM (Original Design Manufacturer) wire mesh stands out for its customized solutions and specialized applications. Understanding the range of ODM wire mesh products can help businesses make informed decisions when selecting the appropriate type for their needs.

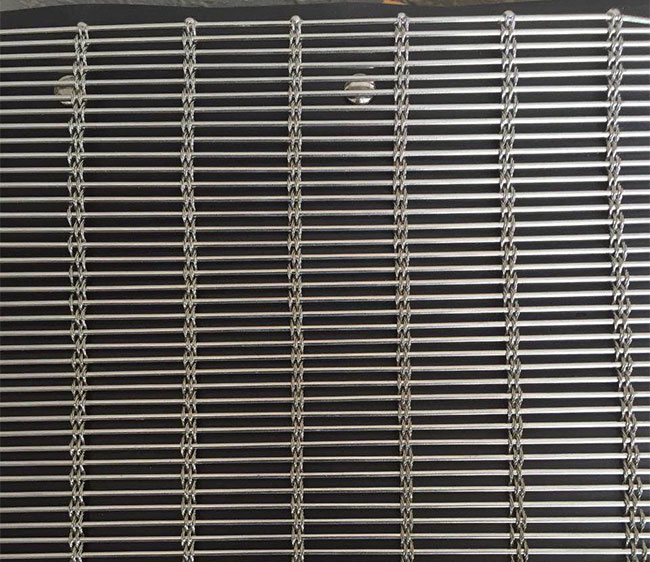

ODM wire mesh refers to wire mesh products designed and manufactured by a company that specializes in producing components based on custom specifications provided by clients. This relationship allows for the creation of unique products that fulfill specific operational requirements in various industries. The range of ODM wire mesh encompasses a variety of materials, weave patterns, and finishes, making it suitable for countless applications.

Understanding ODM Wire Mesh A Comprehensive Overview

The material used in ODM wire mesh also varies significantly, which is pivotal in determining its suitability for different applications. Common materials include stainless steel, galvanized steel, aluminum, and plastic. Stainless steel, known for its corrosion resistance and durability, is often used in applications that require longevity and strength, such as in food processing or pharmaceuticals. On the other hand, galvanized steel is widely favored for its cost-effectiveness and anti-corrosive properties for outdoor applications, while aluminum offers lightweight options for easy handling and installation.

odm wire mesh the range

Different weave patterns are another critical aspect of ODM wire mesh. The type of weave can impact the mesh’s strength, airtiness, and overall functionality. Common weaves include plain weave, twill weave, and Dutch weave, each serving distinct purposes. For instance, a plain weave is often used for applications requiring a high degree of visibility and airflow, such as security screens, while a Dutch weave is preferred in situations where fine filtration is essential, such as in chemical processing.

The finishing processes applied to ODM wire mesh are equally significant. These may involve treatments such as powder coating, anodizing, or electroplating, which enhance the mesh’s durability and aesthetic appeal. A well-applied finish can protect the wire mesh from environmental factors, extending its lifespan and ensuring consistent performance.

In terms of applications, ODM wire mesh can be found in industries ranging from construction and architecture to agriculture and engineering. It is used in fencing systems, sieving materials, safety barriers, and even architectural facades. The versatility of ODM wire mesh means that it can be adapted to meet the specific needs of any project, large or small.

In conclusion, the range of ODM wire mesh products is vast and intricate, offering tailored solutions that cater to diverse industrial needs. By understanding its customization options, material selections, weave patterns, and finishing techniques, businesses can effectively leverage ODM wire mesh to enhance their operations and achieve their specific objectives. Investing in the right wire mesh solutions can lead to improved efficiency, safety, and overall success in various applications.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025