okt . 31, 2024 18:30 Back to list

Custom Metal Wire Weaving Solutions for Your OEM Needs and Applications

The Versatility of OEM Metal Wire Weaving

In today's manufacturing landscape, the need for customized products is paramount. OEM (Original Equipment Manufacturer) metal wire weaving serves as an essential process for industries seeking tailored solutions. This technique not only enhances functionality but also broadens the spectrum of design possibilities in various applications.

The Versatility of OEM Metal Wire Weaving

One of the primary advantages of OEM metal wire weaving is its adaptability to various industries. In construction, for instance, woven wire mesh is used for reinforcement in concrete structures and as security fencing. Its strength and durability make it a preferred choice for ensuring safety and stability. In the automotive sector, metal wire products can be designed for specific vehicle parts, enhancing performance while reducing weight.

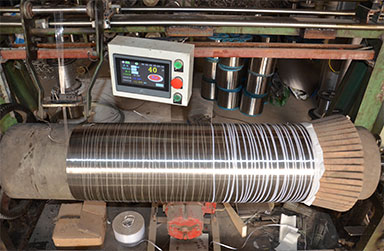

oem metal wire weaving

Another significant sector that benefits from this technology is the textile industry. OEM metal wire weaving creates unique designs that are both practical and visually engaging. Items such as metal fabric or wire sculptures find a place in interior design, showcasing the blend of art and engineering. This fusion results in items that are not only functional but also serve as striking conversation pieces.

Moreover, OEM metal wire weaving supports sustainability. By utilizing recycled metals, manufacturers can produce high-quality woven products while minimizing their environmental impact. The durability of metal wire products also means they have a longer lifespan, further reducing waste.

The customization aspect of OEM metal wire weaving cannot be overlooked. Manufacturers can work closely with clients to develop specific designs, shapes, and functionalities suited to unique applications. This capability enhances the efficiency and satisfaction of end-users, leading to more innovative products on the market.

In conclusion, OEM metal wire weaving stands as a vital process in modern manufacturing, offering versatility and customization across various industries. Its applications range from construction to art, highlighting the harmonization of functionality and aesthetics. As industries continue to evolve, the importance of innovative manufacturing techniques like metal wire weaving will only grow, paving the way for new possibilities and advancements. This adaptability not only meets the demands of today but also sets the stage for future innovations in design and function.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025