okt . 11, 2024 03:08 Back to list

oem steel woven wire

The Versatile World of OEM Steel Woven Wire

In the ever-evolving landscape of industrial materials, OEM (Original Equipment Manufacturer) steel woven wire has carved out a vital niche. Its unique properties make it a preferred choice for a variety of applications across numerous industries. This article explores the characteristics, manufacturing processes, applications, and advantages of OEM steel woven wire, illustrating its significance in modern manufacturing.

What is OEM Steel Woven Wire?

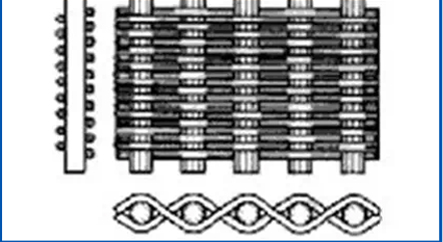

OEM steel woven wire refers to wire that is manufactured specifically for original equipment manufacturers. The wire can be woven into various mesh configurations, offering diverse sizes and shapes tailored to meet the specific requirements of different applications. Steel as a base material provides strength, durability, and resistance to wear and tear, making it an ideal component for a myriad of industrial uses.

Characteristics of OEM Steel Woven Wire

One of the defining characteristics of OEM steel woven wire is its tensile strength. The wire is available in varying thicknesses and gauges, allowing engineers and designers to select the appropriate type for their particular application. Additionally, this woven wire is typically resistant to corrosion, especially when treated with protective coatings or made from stainless steel. Other essential features include flexibility, which allows for custom shapes, and aeration, enabling air and liquid to pass through the mesh easily.

Manufacturing Process

The manufacturing process of OEM steel woven wire involves several steps, starting from the selection of raw materials. High-quality steel is chosen based on the specific requirements of the end products. Once the steel is processed into wire, it undergoes a weaving phase. This phase can employ various techniques, such as plain weave, twill weave, or dutch weave, each offering unique properties suitable for different applications. After weaving, the wire mesh may be subjected to treatments, such as galvanization or coating, to enhance its corrosion resistance and durability.

Applications of OEM Steel Woven Wire

OEM steel woven wire is utilized across a wide range of industries, including

oem steel woven wire

1. Construction In construction, woven wire is often used in concrete reinforcement, providing added strength and stability to structures. It is also utilized in fencing and barriers, contributing to security and safety.

2. Mining and Agriculture In the mining sector, woven wire is employed for screening and separating materials. Similarly, in agricultural applications, it is used in animal enclosures and crop protection.

3. Industrial Filtration OEM steel woven wire is essential in filtration systems, where it serves as a medium for separating solids from liquids and gases. Its precise mesh openings ensure effective filtration across various industrial processes.

4. Architecture and Design In modern architecture, woven wire is increasingly used as a decorative element in facades and interiors, showcasing its aesthetic versatility while maintaining structural integrity.

Advantages of OEM Steel Woven Wire

The advantages of using OEM steel woven wire are manifold. Firstly, its strength and durability make it a long-lasting solution, reducing the need for frequent replacements and the associated costs. Secondly, the versatility of customization allows manufacturers to create tailored products that meet exact specifications, enhancing operational efficiency.

Moreover, with advancements in manufacturing technology, the production of OEM steel woven wire can be done at scale, ensuring consistent quality and reliability. Lastly, the eco-friendly aspect of steel, being recyclable, contributes to a more sustainable manufacturing process, aligning with global goals for environmental conservation.

Conclusion

In conclusion, OEM steel woven wire stands out as a crucial material in a myriad of applications, from construction and filtration to agriculture and architectural design. Its strength, durability, flexibility, and the potential for customization make it an invaluable asset in modern manufacturing. As industries continue to evolve and innovate, the demand for high-quality OEM steel woven wire is expected to soar, underscoring its importance in shaping the future of industrial materials. Whether you are an engineer, architect, or manufacturer, understanding the benefits and applications of OEM steel woven wire can lead to better product development and enhanced functionality in your projects.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025