nóv . 01, 2024 13:28 Back to list

High Precision OEM Fine Wire Mesh for Diverse Applications

Understanding OEM Super Fine Wire Mesh Applications and Benefits

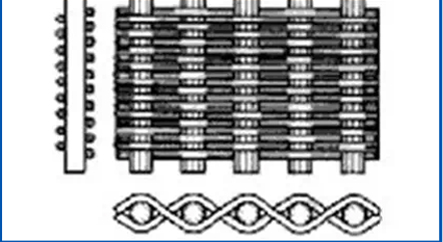

In the world of industrial manufacturing and specialized applications, OEM (Original Equipment Manufacturer) super fine wire mesh has emerged as a crucial component across various sectors. This highly engineered material features extremely fine openings that provide exceptional filtration, separation, and protective capabilities. As industries strive for efficiency and quality, the adoption of super fine wire mesh has become increasingly prevalent.

Key Features of OEM Super Fine Wire Mesh

OEM super fine wire mesh is typically made from stainless steel or other high-quality materials, designed to meet specific industrial requirements. The mesh is characterized by its uniform wire diameter and precise weaving techniques, resulting in consistent mesh openings that can range from a few microns to several millimeters. This degree of control makes it ideal for applications that require high precision and reliability.

One of the standout features of super fine wire mesh is its exceptional durability. Being produced from corrosion-resistant materials, it can withstand harsh environments, making it suitable for use in chemical processing, food processing, and pharmaceutical applications. Furthermore, its strength and flexibility allow it to be customized into various shapes and sizes, catering to specific equipment or application needs.

Applications of OEM Super Fine Wire Mesh

The applications of OEM super fine wire mesh are vast and varied. In the filtration industry, it plays a critical role in removing impurities from liquids and gases. For instance, it is commonly used in water treatment plants to ensure clean and safe water supply. In the medical and pharmaceutical industries, super fine wire mesh is essential for maintaining sterile conditions and processing sensitive substances.

oem super fine wire mesh

In addition to filtration, super fine wire mesh is utilized in industries such as electronics and aerospace, where precision and reliability are paramount. For example, it is used in the manufacturing of microelectronics, acting as a protective barrier against dust and particles. Similarly, it serves as a crucial component in filtering systems for aircraft engines, ensuring optimal performance and safety.

Benefits of Using OEM Super Fine Wire Mesh

The advantages of OEM super fine wire mesh extend beyond its physical properties. Its use can lead to enhanced efficiency in industrial processes, as it allows for better filtration and separation, leading to improved product quality. This, in turn, can result in cost savings for manufacturers, as cleaner inputs translate to reduced waste and lower operational costs.

Additionally, super fine wire mesh contributes to sustainability efforts. By improving the filtration process, it helps in minimizing pollutants and protecting the environment. Industries that prioritize eco-friendly practices find that incorporating high-quality mesh into their processes can bolster their commitment to sustainability.

Conclusion

In summary, OEM super fine wire mesh is an indispensable material that finds applications across multiple industries. Its unique properties, including durability, precision, and versatility, make it an ideal choice for filtration, separation, and protective measures. As industries continue to evolve and prioritize efficiency, quality, and sustainability, the role of OEM super fine wire mesh will undoubtedly become even more prominent. Adopting this advanced material can lead to significant improvements in operational processes, product quality, and environmental stewardship, underscoring its value in modern manufacturing.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025