Gen . 13, 2025 11:41 Back to list

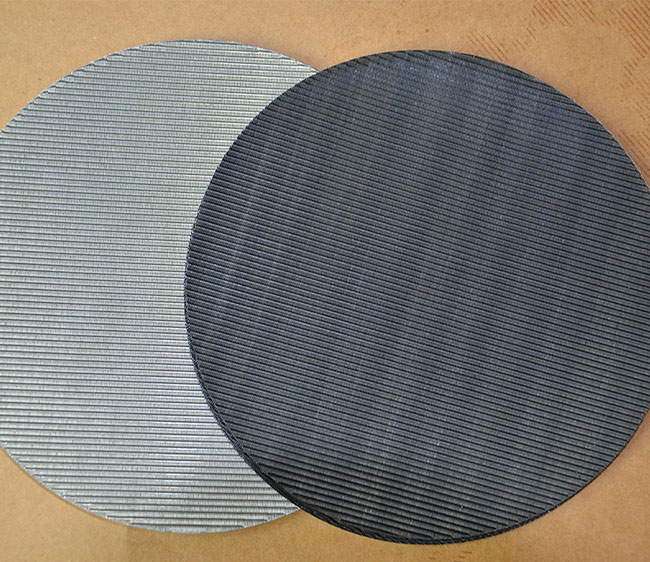

alloy mesh

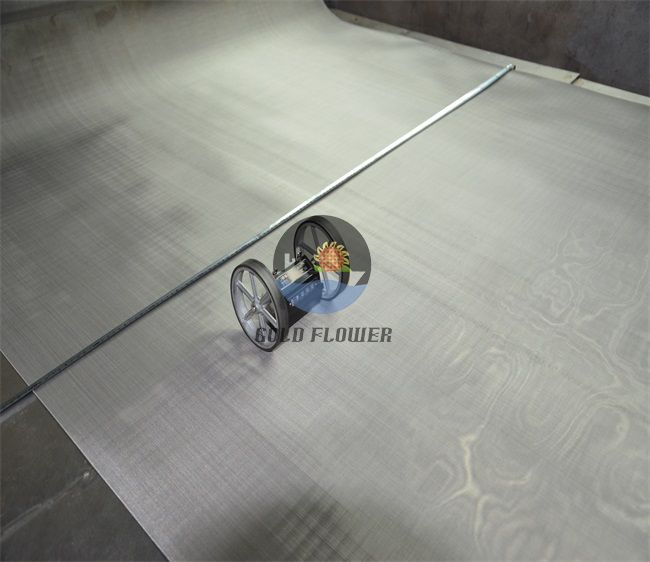

Alloy mesh is a transformative material that has made significant strides in various industrial applications. Its unique combination of strength, flexibility, and durability makes it a preferred choice for engineers and designers seeking reliable materials for demanding projects. This article delves into the compelling features of alloy mesh, showcasing its practical applications and the advantages it brings to diverse industries.

Alloy mesh holds an authoritative position across multiple industries due to its proven track record. In the realm of filtration, it offers unparalleled reliability, ensuring that even in the most demanding conditions, such as in oil refineries or pharmaceutical manufacturing, the filtration systems perform optimally. The consistent quality of filtrates underscores the dependability of alloy mesh solutions, highlighting why so many sectors rely on this material for critical applications. Trustworthiness in materials is a crucial factor for industry professionals when selecting components for their projects. Alloy mesh has earned this trust through rigorous testing and quality assurance processes. Leading manufacturers conduct comprehensive tests to verify that their alloy mesh products comply with the stringent standards required by regulatory bodies. This certification process reassures users that the alloy mesh will perform as expected, maintaining its structural integrity and effectiveness throughout its intended lifespan. In conclusion, alloy mesh is more than just an industrial staple; it's a testament to human innovation and material science advancement. Its widespread use across diverse applications highlights its versatility and reliability. By processing the ideal alloy mesh for each specific application, industries can leverage its superior qualities, leading to enhanced product performance and operational efficiencies. The strategic selection and application of alloy mesh ultimately enable industries to push the boundaries of what is possible, fostering progress and innovation.

Alloy mesh holds an authoritative position across multiple industries due to its proven track record. In the realm of filtration, it offers unparalleled reliability, ensuring that even in the most demanding conditions, such as in oil refineries or pharmaceutical manufacturing, the filtration systems perform optimally. The consistent quality of filtrates underscores the dependability of alloy mesh solutions, highlighting why so many sectors rely on this material for critical applications. Trustworthiness in materials is a crucial factor for industry professionals when selecting components for their projects. Alloy mesh has earned this trust through rigorous testing and quality assurance processes. Leading manufacturers conduct comprehensive tests to verify that their alloy mesh products comply with the stringent standards required by regulatory bodies. This certification process reassures users that the alloy mesh will perform as expected, maintaining its structural integrity and effectiveness throughout its intended lifespan. In conclusion, alloy mesh is more than just an industrial staple; it's a testament to human innovation and material science advancement. Its widespread use across diverse applications highlights its versatility and reliability. By processing the ideal alloy mesh for each specific application, industries can leverage its superior qualities, leading to enhanced product performance and operational efficiencies. The strategic selection and application of alloy mesh ultimately enable industries to push the boundaries of what is possible, fostering progress and innovation.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025