Feb . 16, 2025 04:20 Back to list

buy wire cloth mfg

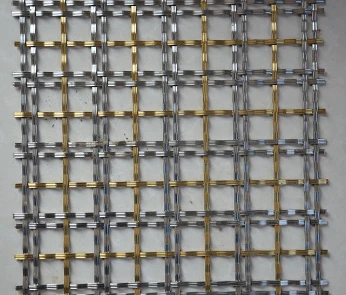

In the dynamic landscape of industrial materials, wire cloth manufacturing represents a pivotal yet often overlooked sector that powerfully bridges the gap between raw metal resources and their countless industrial applications. When looking to buy wire cloth manufacturing products, a discerning approach towards quality, application specificity, and supplier credibility becomes imperative.

Equally significant is the manufacturer's advancement in technological integration within their production processes. The adoption of state-of-the-art machinery not only facilitates precision but also maximizes efficiency, reaching a balance between high production capacity and maintaining fine-tuned accuracy across high-volume orders. Such innovation often extends beyond the manufacturing phase into areas like order tracking and customer support, ensuring a seamless and responsive purchasing experience. Furthermore, authority within the wire cloth manufacturing industry is underscored by regulatory compliance and engagement with industry standards. Accredited certifications from organizations like ISO mark a company's adherence to global standards of quality and environmental safety. This commitment signifies not just an operational baseline of excellence but an ethical stance towards sustainable and socially responsible business practices. Trustworthiness in a supplier extends beyond certifications and visible production efficiencies. It resonates in their capacity for robust customer service and post-purchase support, oriented around building long-term partnerships rather than mere transactions. Reliable manufacturers cultivate this trust with transparency, providing potential clients access to case studies, testimonials, and third-party reviews that validate their product’s performance in real-world applications. Additionally, seasoned manufacturers are keenly aware of the cyclical trends and challenges within the market, offering insightful forecasts and strategies to clients looking to navigate fluctuating supply chain landscapes. In conclusion, purchasing wire cloth manufacturing goods demands a comprehensive evaluation of the supplier's expertise, authority, and operations integrity. A company with a long-standing history of excellence in production precision, technological capabilities, and industry accreditation exemplifies an optimal partner. With the right partner, businesses across various sectors can not only ensure product effectiveness and reliability but also engender a mutually beneficial relationship promising continued innovation and support. In an ever-evolving industrial world, such partnerships symbolically weave the thread between business potential and sustainable success.

Equally significant is the manufacturer's advancement in technological integration within their production processes. The adoption of state-of-the-art machinery not only facilitates precision but also maximizes efficiency, reaching a balance between high production capacity and maintaining fine-tuned accuracy across high-volume orders. Such innovation often extends beyond the manufacturing phase into areas like order tracking and customer support, ensuring a seamless and responsive purchasing experience. Furthermore, authority within the wire cloth manufacturing industry is underscored by regulatory compliance and engagement with industry standards. Accredited certifications from organizations like ISO mark a company's adherence to global standards of quality and environmental safety. This commitment signifies not just an operational baseline of excellence but an ethical stance towards sustainable and socially responsible business practices. Trustworthiness in a supplier extends beyond certifications and visible production efficiencies. It resonates in their capacity for robust customer service and post-purchase support, oriented around building long-term partnerships rather than mere transactions. Reliable manufacturers cultivate this trust with transparency, providing potential clients access to case studies, testimonials, and third-party reviews that validate their product’s performance in real-world applications. Additionally, seasoned manufacturers are keenly aware of the cyclical trends and challenges within the market, offering insightful forecasts and strategies to clients looking to navigate fluctuating supply chain landscapes. In conclusion, purchasing wire cloth manufacturing goods demands a comprehensive evaluation of the supplier's expertise, authority, and operations integrity. A company with a long-standing history of excellence in production precision, technological capabilities, and industry accreditation exemplifies an optimal partner. With the right partner, businesses across various sectors can not only ensure product effectiveness and reliability but also engender a mutually beneficial relationship promising continued innovation and support. In an ever-evolving industrial world, such partnerships symbolically weave the thread between business potential and sustainable success.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025

-

Premium Stainless Steel Weave Mesh for Filtration and Security

NewsJul.29,2025