Nov . 20, 2024 15:03 Back to list

buy woven crimped wire mesh

Exploring the Benefits of Woven Crimped Wire Mesh

In today's diverse industrial landscape, woven crimped wire mesh has emerged as a versatile and essential material. This unique product, predominantly used in various applications such as filtration, fencing, and architectural design, is gaining popularity due to its durability, strength, and adaptability. In this article, we will explore what woven crimped wire mesh is, its benefits, and why you should consider purchasing it for your needs.

What is Woven Crimped Wire Mesh?

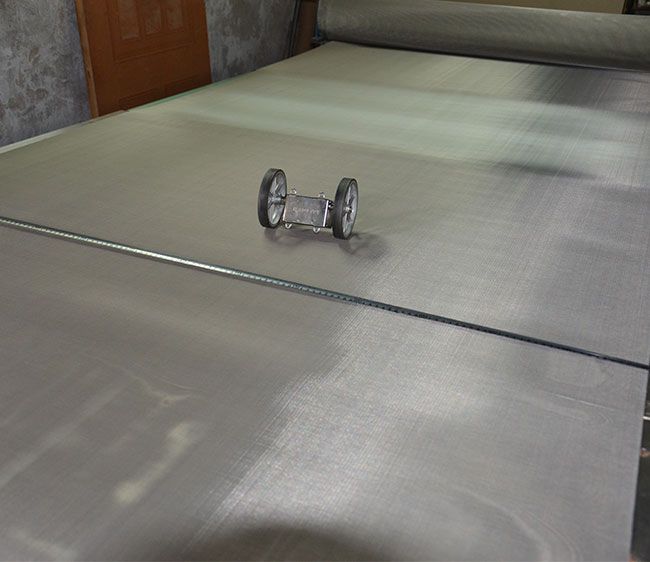

Woven crimped wire mesh is a type of wire mesh made from crimped wires that are woven together to form a fabric of interconnected strands. The crimping process involves the forming of waves or bends in the wire, not only enhancing its structural strength but also allowing for a tighter weave. This method of construction results in a mesh that exhibits both rigidity and flexibility, making it suitable for a broad range of applications.

Applications of Woven Crimped Wire Mesh

1. Filtration One of the most common uses of woven crimped wire mesh is in filtration systems. Its fine openings can effectively capture particulates while allowing fluids to pass through. This makes it ideal for use in water treatment plants, oil refineries, and food processing plants.

2. Fencing and Security Due to its sturdy build, woven crimped wire mesh is an excellent choice for fencing. It can be utilized in creating security barriers, animal enclosures, and even garden fencing. Its strength ensures that it can withstand external forces, making it difficult for intruders or animals to breach.

3. Architectural Features In modern architecture, woven crimped wire mesh is increasingly being used as a design element. It offers a unique aesthetic that can be incorporated into facades, screens, and ceilings, providing beauty and functionality. The material can also improve ventilation and natural light flow while maintaining privacy.

buy woven crimped wire mesh

4. Automotive and Aerospace The automotive and aerospace industries use woven crimped wire mesh for several applications, including air filtration systems and heat shields. Its high-temperature resistance and structural integrity are crucial in these fields.

Benefits of Woven Crimped Wire Mesh

1. Durability One of the standout features of woven crimped wire mesh is its long-lasting durability. Made from high-quality materials like stainless steel, aluminum, or galvanized steel, it can withstand harsh conditions and is resistant to rust and corrosion. This longevity makes it a cost-effective option in the long run, as it requires less frequent replacements.

2. Versatility Woven crimped wire mesh comes in various sizes, openings, and wire diameters, allowing it to be tailored for specific applications. Whether you need a fine mesh for filtration or a robust mesh for fencing, there is likely a woven crimped wire mesh that meets your requirements.

3. Easy Maintenance Maintaining woven crimped wire mesh is a breeze. It can be easily cleaned by washing or hosing down, which is especially important in industries where hygiene is critical, such as food processing and pharmaceuticals.

4. Cost-Effective While upfront costs can vary depending on materials and specifications, the overall lifespan and performance of woven crimped wire mesh make it a financially savvy choice. Its durability and ease of maintenance contribute to lower long-term costs.

Conclusion

In summary, woven crimped wire mesh is a highly adaptable and durable material that can be employed in a wide array of industries. Its unique characteristics offer advantages such as longevity, flexibility, and ease of maintenance, making it a preferred choice for many applications. If you are considering purchasing woven crimped wire mesh, understand your specific needs and consult with suppliers to select the right type for your project. The benefits it offers are undeniable, making it a smart investment for both industrial and architectural purposes.

share

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025