Nov . 20, 2024 02:36 Back to list

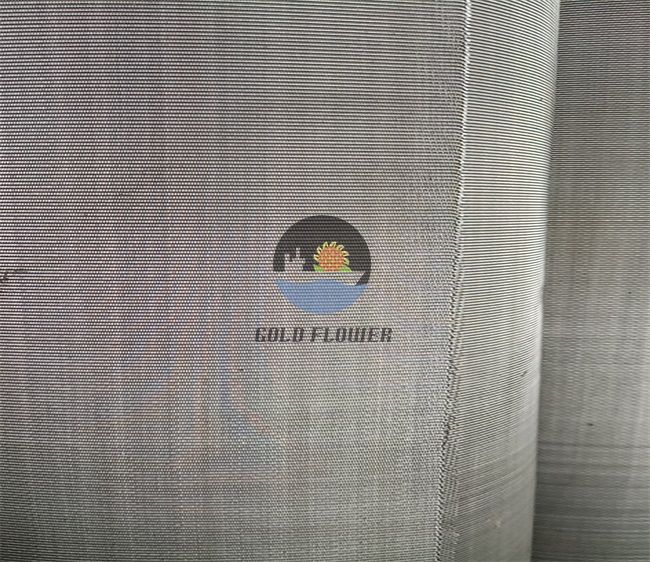

high quality very fine mesh screen

The Importance of High-Quality Very Fine Mesh Screens

In numerous industries and applications, high-quality very fine mesh screens play a critical role in the effectiveness and efficiency of various processes. From pharmaceuticals to food production and even environmental applications, the significance of using the right mesh screen cannot be overstated. This article delves into the different aspects of high-quality fine mesh screens, including their construction, applications, benefits, and considerations for selection.

Construction of Fine Mesh Screens

High-quality very fine mesh screens are typically constructed from durable materials such as stainless steel, nylon, or polyester. The choice of material often depends on the specific application and the environmental conditions common to that environment. For instance, stainless steel is highly resistant to corrosion, making it an ideal option for industries involving chemicals or where cleanliness is paramount.

The mesh’s characteristics, such as wire diameter and aperture size, also play a crucial role. Very fine mesh screens often have a wire diameter considerably thinner than standard screens, allowing them to filter smaller particles effectively. The aperture size, which refers to the openings in the mesh, is critical for determining the level of filtration. Fine mesh screens often boast an aperture size of less than 1 millimeter, which enables them to trap even the tiniest particles, allergens, and contaminants that would otherwise go unnoticed.

Applications of Fine Mesh Screens

High-quality very fine mesh screens are utilized across various sectors

1. Pharmaceuticals In pharmaceutical manufacturing, very fine mesh screens are essential for processes such as sieving powders and filtering liquids. They ensure that particles meet precise size specifications, thus aiding in the production of high-quality medications.

2. Food Processing In the food industry, fine mesh screens are used to sift flour, separate particles in juices, and ensure that ingredients are of uniform size. They help maintain food safety by filtering out contaminants and preventing undesirable substances from entering the final product.

3. Environmental Applications These screens play a vital role in water treatment and air purification systems. In these cases, they are used to capture particulate matter, pollutants, and other harmful substances, thereby contributing to cleaner water and air.

4. Industrial Applications Within manufacturing processes, very fine mesh screens facilitate the separation of materials, such as metals and plastics, during recycling operations.

high quality very fine mesh screen

Benefits of High-Quality Fine Mesh Screens

The benefits of utilizing high-quality very fine mesh screens extend beyond just filtration. Some of the most notable benefits include

- Improved Efficiency High-quality screens ensure that processes run smoothly and effectively, reducing downtime caused by blockages and maintenance.

- Increased Product Quality By filtering out unwanted particles, these screens help maintain the integrity and quality of the final product, which is critical in sectors like pharmaceuticals and food.

- Longevity and Durability Investing in high-quality materials means that the screens will last longer, ultimately offering better value for money over time.

- Customization Fine mesh screens can often be customized to meet specific application requirements, ensuring that they perform optimally in the intended environment.

Considerations for Selection

When selecting a very fine mesh screen, several factors should be considered to ensure optimal performance. First, the specific application should dictate the material choice; for example, corrosive environments may necessitate stainless steel. Additionally, understanding the particle size and type being filtered will help determine the appropriate aperture size and mesh density. Finally, evaluating the screen’s compatibility with existing systems is essential to ensure proper integration.

Conclusion

High-quality very fine mesh screens are invaluable across various industries, providing efficient filtration and contributing to product quality and safety. By understanding their construction, applications, and benefits, businesses can make informed decisions when selecting the right mesh screens for their needs. In a world where precision and quality are paramount, investing in high-quality fine mesh screens is a necessary step towards achieving operational excellence.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025