Dic . 04, 2024 12:55 Back to list

odm steel woven wire

The Versatility of ODM Steel Woven Wire An In-Depth Exploration

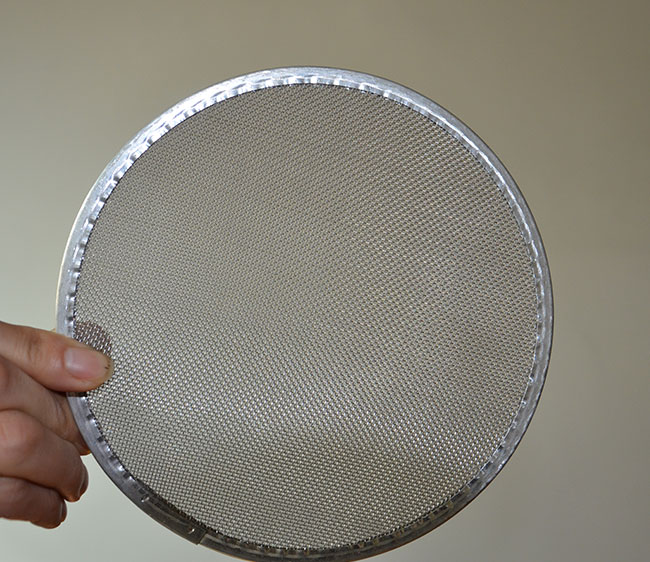

In the realm of industrial materials, ODM steel woven wire has emerged as a significant player, offering versatility and strength across various applications. This type of wire is constructed using high-quality steel strands that are interwoven to create a robust, flexible mesh. This article provides an overview of ODM steel woven wire, its applications, benefits, and the factors that contribute to its popularity in different industries.

Understanding ODM Steel Woven Wire

ODM stands for Original Design Manufacturer, which signifies a company that designs and manufactures products based on the specifications of another company. When it comes to steel woven wire, ODM companies often cater to specific client needs, producing tailored solutions that address unique industrial challenges.

Steel woven wire is characterized by its high tensile strength and durability, making it ideal for applications where resilience is critical. The weaving process enhances the wire's sturdiness while allowing it to maintain flexibility, which is advantageous in various settings where traditional materials might fail.

Applications of ODM Steel Woven Wire

The applications of ODM steel woven wire are incredibly diverse, spanning multiple industries

1. Construction and Architecture In the construction sector, welded wire and meshes are often used for reinforcement in concrete structures. Their ability to hold together under significant weight and stress makes them essential components in constructing safe buildings, bridges, and other infrastructures.

2. Agriculture Farmers leverage steel woven wire for fencing and protecting crops. The durable mesh serves as an effective barrier against predators while allowing air and sunlight to reach the plants. It can also be utilized in creating cages for animals and securely enclosing livestock areas.

3. Filtration and Separation In industries such as food processing, pharmaceuticals, and water treatment, ODM steel woven wire is utilized to create filters that separate solid particles from liquids. Its precision and uniformity ensure high efficiency in filtration applications, contributing to higher quality products.

odm steel woven wire

4. Mining and Quarrying The mining industry often employs steel woven wire screens for sorting and sizing materials. The strength and durability of the wire determine its effectiveness under heavy loads while also providing a long lifespan.

5. Automotive and Aerospace In the automotive and aerospace sectors, steel woven wire is used in manufacturing components that require high strength-to-weight ratios. It is also applied in various filtration systems that ensure the efficiency and safety of the machinery.

Advantages of ODM Steel Woven Wire

Opting for ODM steel woven wire comes with several benefits

- Customization ODM manufacturers can tailor the mesh specifications, including gauge, width, and weave pattern, to meet specific customer requirements. This customization ensures that the wire fits perfectly into the intended application.

- Durability Steel, being significantly stronger than alternative materials, provides a longer lifespan for woven wire products. This durability translates to lower maintenance costs and reduced frequency of replacements.

- Resistance to Environmental Factors ODM steel woven wire can be treated or coated to enhance its resistance to corrosion, rust, and other environmental factors, making it suitable for both indoor and outdoor applications.

- Cost-Effectiveness While the initial investment might be higher than other materials, the longevity and reduced maintenance needs of steel woven wire can result in cost savings over time.

Conclusion

ODM steel woven wire is a vital material in various industries due to its strength, flexibility, and customization options. Whether used in construction, agriculture, filtration, or niche markets such as automotive and aerospace, its advantages are undeniable. As industries continue to evolve and demand more robust materials, the importance of ODM steel woven wire is expected to grow, paving the way for innovative applications and solutions in the future. Embracing this versatile material could indeed be a game changer for many sectors, enhancing productivity and safety across the board.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025