Nov . 05, 2024 23:25 Back to list

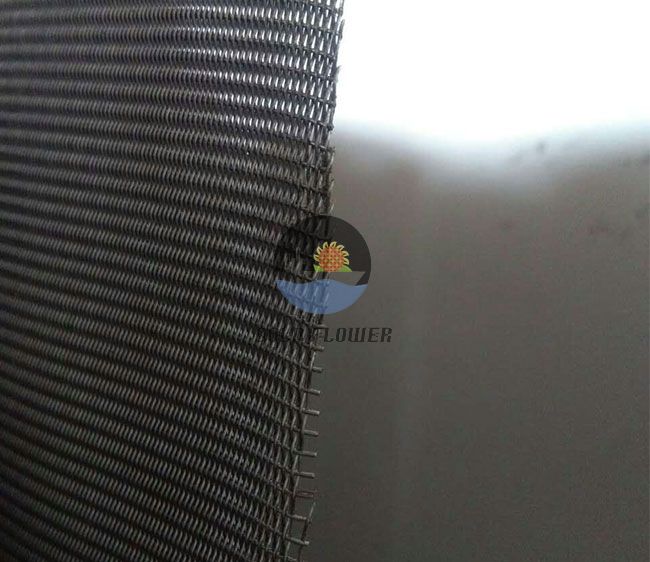

oem stainless steel wire mesh netting

The Versatility and Benefits of OEM Stainless Steel Wire Mesh Netting

Stainless steel wire mesh netting is an indispensable material in various industries, ranging from construction and manufacturing to agriculture and food processing. With its high resistance to corrosion and robust mechanical properties, stainless steel wire mesh offers exceptional durability and versatility that makes it a preferred choice for many applications. Original Equipment Manufacturers (OEMs) can particularly benefit from utilizing this material due to its customizable nature and the wide range of applications it supports.

One of the key advantages of OEM stainless steel wire mesh netting is its adaptability. OEMs can produce mesh netting in varying specifications tailored to specific needs. This customization includes different wire diameters, mesh openings, and even types of stainless steel, such as 304 or 316 grades, depending on the application and environmental conditions. For instance, while 304 stainless steel is suitable for most applications due to its excellent corrosion resistance and affordability, 316 stainless steel offers superior protection against saltwater and acidic environments, making it ideal for marine applications.

In construction, stainless steel wire mesh is often used in concrete reinforcement, preventing cracking and increasing structural integrity. In agricultural applications, the mesh serves as protective fencing for livestock, offering safety while allowing visibility and airflow. Its durability ensures that it withstands harsh weather conditions, making it a reliable choice for long-term use on farms and ranches.

oem stainless steel wire mesh netting

The food processing industry also benefits significantly from stainless steel wire mesh netting. It is commonly used in filtration systems, processing equipment, and as barriers to prevent contamination. Since stainless steel is non-reactive and easy to clean, it meets stringent hygiene standards, ensuring that food products are safe and free from contaminants. OEMs can design bespoke mesh solutions that fit specific industrial equipment, enhancing both efficiency and safety in food production environments.

Another vital use of stainless steel wire mesh is in the realm of filtration. Industrial filters made from this material are highly effective in separating solids from liquids, air, and other gases. The mesh is used in various applications, including oil filtration systems, water treatment facilities, and HVAC systems. With its strong framework, stainless steel wire mesh not only prolongs the lifespan of filtration equipment but also enhances the quality of the filtered substance.

Additionally, the aesthetic appeal of stainless steel wire mesh cannot be overlooked, especially in architectural applications. Architects and designers often use it for decorative facades, security screens, and railings, combining functionality with modern design. The shiny finish of stainless steel adds an elegant touch, while its strength ensures safety and durability.

In summary, OEM stainless steel wire mesh netting is a versatile and valuable material across numerous industries. Its ability to be customized for specific applications, combined with its robust properties and aesthetic appeal, makes it an essential component in various manufacturing, agricultural, and architectural processes. As industries continue to seek durable and efficient solutions, stainless steel wire mesh will undoubtedly remain a preferred choice for OEMs aiming to meet the diverse needs of their clients. By investing in quality stainless steel wire mesh, businesses can enhance their production processes, ensuring safety, efficiency, and longevity in their operations.

share

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025

-

Decorative Metal Mesh for Radiator Covers Custom Durable Mesh Panels

NewsJun.10,2025