Dec . 20, 2024 10:38 Back to list

best mesh galvanized steel

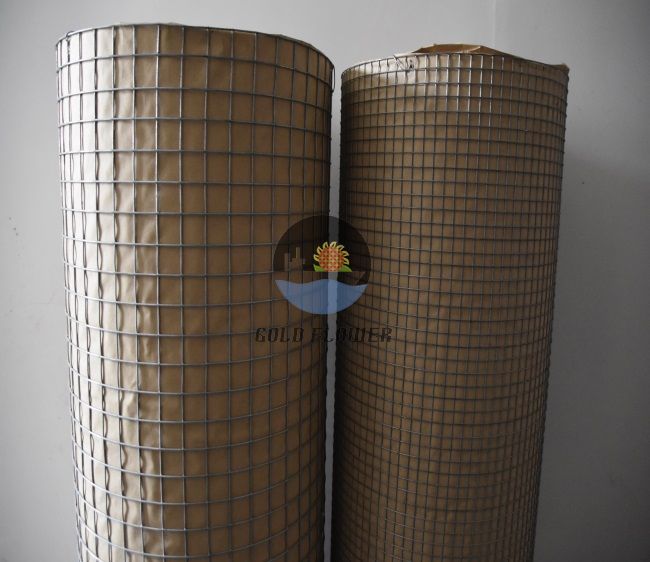

The Best Mesh Galvanized Steel An Essential Material for Versatile Applications

When it comes to construction and manufacturing, materials play a pivotal role in determining the quality and durability of the final product. One material that has consistently proven to be reliable across various industries is mesh galvanized steel. This versatile product combines the corrosion resistance of galvanized steel with the durability and flexibility of mesh, making it ideal for a wide array of applications. In this article, we will explore the properties, benefits, and myriad uses of mesh galvanized steel.

What is Mesh Galvanized Steel?

Mesh galvanized steel is produced by welding or weaving together steel wires to create a network of interconnected strands. This mesh is then coated with a layer of zinc to enhance its resistance to rust and corrosion. The galvanization process involves either hot-dipping or electroplating, both of which provide a protective barrier that significantly extends the lifespan of the steel. The combination of mesh and galvanized steel results in a lightweight yet robust material that can withstand harsh environmental conditions.

Key Properties and Benefits

1. Corrosion Resistance The most significant advantage of galvanized steel is its ability to resist corrosion. This property is especially crucial in outdoor settings or environments where moisture and chemicals may be present. The zinc coating protects the underlying steel from the elements, reducing maintenance costs and extending service life.

2. Strength and Durability Mesh galvanized steel exhibits high tensile strength, making it suitable for various structural applications. Its robust nature allows it to bear heavy loads while maintaining its shape and integrity over time.

3. Versatility Whether used in construction, agricultural, industrial, or residential applications, mesh galvanized steel can adapt to numerous requirements. It can be fabricated into various shapes and sizes, making it applicable in many fields, from fencing to reinforcing concrete.

4. Cost-Effectiveness Although the initial investment in mesh galvanized steel may be higher than that of some alternative materials, its long-term durability and low maintenance requirements often make it a more cost-effective solution for many projects.

5. Easy Installation The lightweight nature of mesh galvanized steel facilitates easier transportation and installation. Additionally, it can be easily cut, shaped, or welded, enabling seamless integration into different projects.

best mesh galvanized steel

Applications of Mesh Galvanized Steel

The range of applications for mesh galvanized steel is extensive. Here are some of the common uses

- Fencing Its robust structure and corrosion resistance make mesh galvanized steel an excellent choice for fencing solutions, providing security for residential and commercial properties.

- Reinforcement In construction, mesh galvanized steel is often used as reinforcement in concrete structures. It enhances the strength of concrete slabs, walls, and columns, ensuring durability and longevity.

- Agricultural Fencing Farmers frequently use mesh galvanized steel to create enclosures for livestock and crops, as it can withstand the harsh outdoor conditions.

- Walkways and Grates The mesh design allows for drainage, making it suitable for walkways, grates, and platforms in industrial settings where water or chemicals might accumulate.

- Shelving and Storage In warehouses and storage facilities, mesh galvanized steel is utilized to create shelves and racks, optimizing the organization and warehousing of goods.

Conclusion

Mesh galvanized steel is undeniably one of the best materials available for a multitude of uses due to its unique combination of strength, corrosion resistance, and versatility. Whether applied in construction, agriculture, or industrial settings, it provides a reliable solution that meets the diverse needs of modern society. By choosing mesh galvanized steel for a project, stakeholders can ensure longevity, efficiency, and cost-effectiveness, making it an indispensable material in today’s market. Embracing this innovative product can significantly enhance the quality and durability of any construction or manufacturing endeavor, paving the way for success in various applications.

share

-

CE Certified 250 Micron SS Mesh - Precision Filtration & Strength

NewsAug.21,2025

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025