Oct . 08, 2024 00:02 Back to list

best wire mesh woven

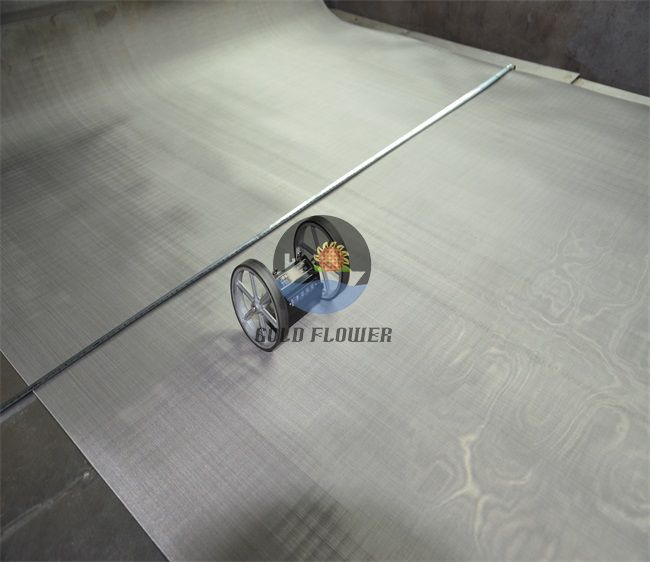

Exploring the Best Wire Mesh Woven Materials

Wire mesh woven materials are integral to a variety of applications across different industries. From construction to agriculture, the versatility of wire mesh makes it a preferred choice for many engineers and designers. This article delves into the best wire mesh woven options available today, exploring their benefits, applications, and manufacturing processes.

What is Wire Mesh Woven?

Wire mesh woven is created by interlacing wires in a grid pattern. This weaving offers a sturdy structure capable of withstanding stress, making it highly effective for various uses. The materials used in the production of wire mesh can vary, including stainless steel, galvanized steel, copper, and more, each offering unique properties suited for specific applications.

Benefits of Wire Mesh Woven Materials

One of the significant advantages of wire mesh woven is its strength and durability. For instance, stainless steel wire mesh is resistant to corrosion and rust, making it ideal for outdoor applications or environments with high moisture. Additionally, its tensile strength ensures that it can support heavy loads, making it suitable for construction and architectural projects.

Another advantage is the flexibility in design. Wire mesh comes in various sizes and patterns, providing choices that can be tailored to specific requirements. Whether you need large openings for ventilation or fine mesh for filtration, there is a woven wire mesh product that fits the bill. This adaptability makes it a favored material in agricultural applications, such as fencing and planting, where different mesh sizes can help protect crops from pests.

Applications of Wire Mesh Woven

best wire mesh woven

The applications of wire mesh woven materials are vast. In the construction industry, it is used for reinforcement in concrete, providing added strength to structures. It is also prevalent in architectural designs, serving as decorative elements or safety barriers.

In manufacturing, wire mesh plays a vital role in filtering and screening processes. Industries such as food and beverage, pharmaceuticals, and chemicals use woven wire mesh for separation, ensuring quality control in their products.

Agriculture benefits significantly from wire mesh woven materials. Farmers use it to create protective fencing around livestock, preventing predators from accessing their animals. Additionally, wire mesh is employed in greenhouse construction, allowing for optimal air circulation while keeping pests at bay.

Manufacturing Process

The manufacturing of wire mesh woven involves several steps. First, raw wires are chosen based on the required properties. The wires are then cut to length and woven using specialized machines that accurately create the grid pattern. Post-weaving processes, such as galvanization or coating, may be applied to enhance corrosion resistance and durability, ensuring that the final product can withstand various environmental conditions.

Conclusion

In summary, wire mesh woven materials are indispensable across numerous industries due to their strength, versatility, and adaptability. From reinforcing structures to protecting crops, these materials continually prove themselves as a reliable choice. As industries evolve and new applications emerge, the demand for high-quality wire mesh woven products is poised to remain strong, paving the way for innovative designs and uses in the future.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025