Dec . 18, 2024 19:44 Back to list

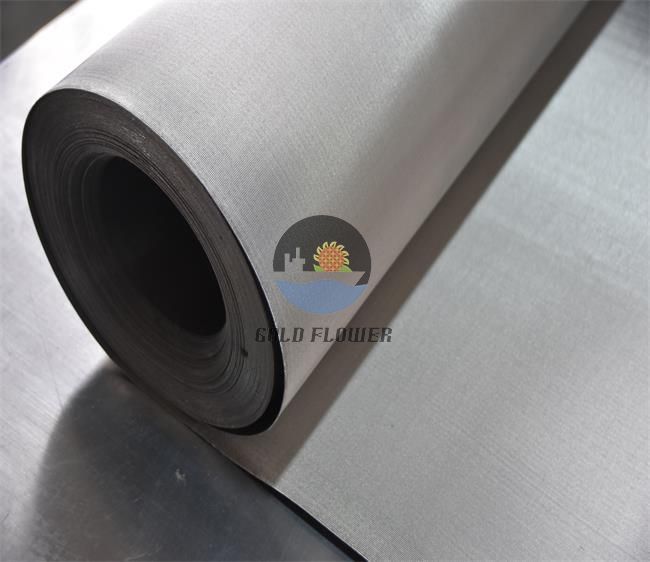

best wire screens

The Best Wire Screens A Comprehensive Guide

Wire screens, also known as wire mesh or wire cloth, are essential tools in various industries and applications, ranging from construction and mining to food processing and environmental management. This article aims to delve into the characteristics, types, applications, benefits, and considerations when selecting the best wire screens for your specific needs.

Characteristics of Wire Screens

Wire screens are made from weaving or welding together thin strands of metal wire. They come in different gauges, materials, and mesh sizes, which determine their strength, durability, and ability to filter specific materials. The most common materials used are stainless steel, carbon steel, aluminum, and various alloys. The choice of material largely depends on the application, as different environments may require enhanced corrosion resistance or specific mechanical properties.

Types of Wire Screens

1. Woven Wire Screens These are created by weaving wire strands together to form a mesh. They are widely used because of their versatility and the ability to customize mesh sizes to meet specific filtration needs.

2. welded Wire Screens Welded wire screens are constructed by welding wires at their intersections. This type is particularly robust and suitable for applications requiring strong structural integrity.

3. Perforated Metal Screens While not technically wire screens, perforated metal screens are often used in conjunction with wire screens. They consist of metal plates punctured with holes and can provide additional filtering options.

4. Polyester and Polypropylene Screens For applications that involve corrosive materials or require lightweight options, synthetic screens made from polyester, polypropylene, or nylon may be ideal, albeit less durable than metal options.

Applications of Wire Screens

Wire screens have a broad range of applications. In the construction industry, they are often used for concrete reinforcement and for protecting areas from debris. In the agriculture sector, wire screens serve as sifting and filtering tools for seeds and grains. The mining and mineral processing industries use them extensively for sorting materials, while food processing facilities rely on wire screens for efficient cleaning and separating processes. Furthermore, wire screens are invaluable in wastewater treatment facilities, where they help remove solids from liquid waste.

Benefits of Wire Screens

best wire screens

2. Versatility Wire screens can be customized in terms of mesh size, material, and design to suit a wide range of applications, enhancing their utility across various industries.

3. Cost-Effectiveness The durability and long lifespan of wire screens can reduce replacement costs over time, making them a cost-effective choice for businesses.

4. Efficiency Properly designed wire screens can significantly improve the efficiency of filtration processes, whether in industrial applications or environmental management.

Selecting the Best Wire Screens

When selecting the best wire screens for your applications, several factors must be considered

1. Material Choose a material that can withstand the specific environmental conditions it will face. For instance, stainless steel is ideal for corrosive environments, while carbon steel may be better for applications where weight is a concern.

2. Mesh Size The mesh size should correspond to the materials being filtered or separated. Smaller mesh sizes are better for fine particles, while larger sizes are suited for coarser materials.

3. Thickness and Gauge The thickness of the wire can affect the screen's overall strength. Thicker wires typically offer better durability but may reduce flexibility.

4. Wire Configuration Depending on the application, you may choose between woven or welded wire screens, with the latter offering superior strength.

Conclusion

Wire screens are indispensable tools across various industries, providing reliable and efficient filtering solutions. Understanding the different types, applications, and characteristics can help businesses make informed decisions about their screening needs. By prioritizing durability, efficiency, and the right specifications, industries can harness the full potential of wire screens, ensuring optimal performance in their operations. Whether you are in construction, agriculture, or waste management, selecting the best wire screens can make a significant difference in the success of your projects.

share

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025