Feb . 13, 2025 09:33 Back to list

buy 120 micron stainless steel mesh

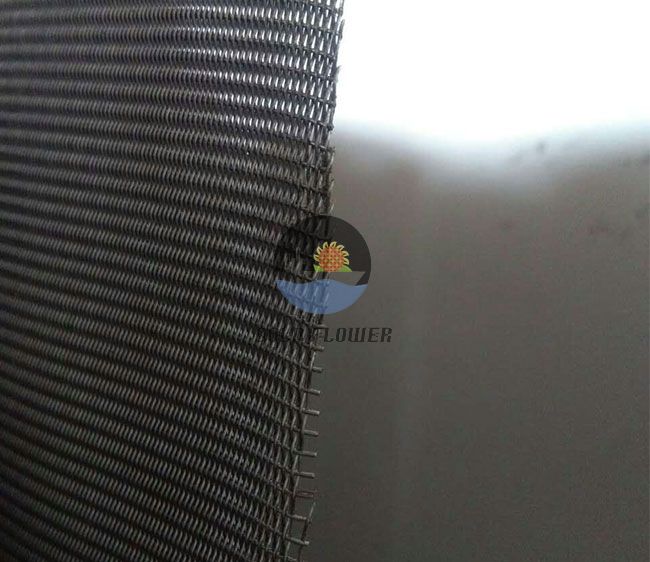

When considering the purchase of a 120 micron stainless steel mesh, it’s crucial to understand why stainless steel mesh is a preferred choice across various industries and applications. Renowned for its durability, resistance to corrosion, and strength, stainless steel mesh offers a sophisticated solution for filtration and sieving tasks.

Trustworthiness in the industry is further cemented by the mesh’s non-reactive nature. Unlike meshes made from other materials, stainless steel does not release harmful contaminants, making it the ideal choice for sensitive environments. This non-reactivity makes it a preferred choice for laboratories and places requiring sterile conditions. Furthermore, the ability to withstand rigorous cleaning and sterilization processes without degrading extends its application into environments such as hospitals and laboratories. Whether it is subjected to steam cleaning processes or chemical sterilization, the mesh’s properties remain intact, ensuring consistent performance. Selecting a 120 micron stainless steel mesh not only involves understanding its technical specifications but also considering the supplier's credibility. Seek out suppliers who demonstrate transparency in their manufacturing processes and who comply with international standards such as ISO certification. This guarantees the mesh is manufactured under stringent quality controls, providing extra peace of mind in its deployment. In summary, the 120 micron stainless steel mesh offers an exceptional combination of precision, durability, and reliability. Its widespread application and consistent performance have cemented its position as an indispensable component in various industries. Whether for filtration, separation, or straining, its role is indispensable in ensuring efficiency and safety in operations.

Trustworthiness in the industry is further cemented by the mesh’s non-reactive nature. Unlike meshes made from other materials, stainless steel does not release harmful contaminants, making it the ideal choice for sensitive environments. This non-reactivity makes it a preferred choice for laboratories and places requiring sterile conditions. Furthermore, the ability to withstand rigorous cleaning and sterilization processes without degrading extends its application into environments such as hospitals and laboratories. Whether it is subjected to steam cleaning processes or chemical sterilization, the mesh’s properties remain intact, ensuring consistent performance. Selecting a 120 micron stainless steel mesh not only involves understanding its technical specifications but also considering the supplier's credibility. Seek out suppliers who demonstrate transparency in their manufacturing processes and who comply with international standards such as ISO certification. This guarantees the mesh is manufactured under stringent quality controls, providing extra peace of mind in its deployment. In summary, the 120 micron stainless steel mesh offers an exceptional combination of precision, durability, and reliability. Its widespread application and consistent performance have cemented its position as an indispensable component in various industries. Whether for filtration, separation, or straining, its role is indispensable in ensuring efficiency and safety in operations.

share

Latest news

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025