Feb . 10, 2025 10:08 Back to list

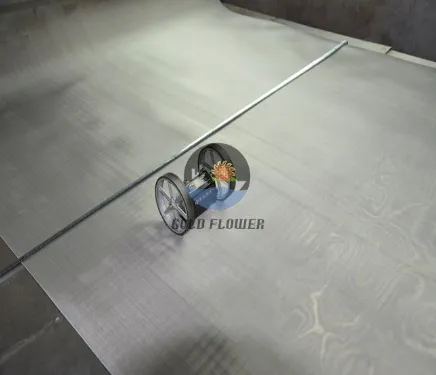

ce certification stainless steel wire mesh for screen printing

When considering the purchase of a 1/8 wire mesh screen, it’s essential to arm yourself with a blend of real-world experience, expert insights, and authoritative information to make an informed decision. These screens, often employed in diverse applications, offer a variety of benefits and specifications tailored for specific uses. Here, we delve into the critical aspects to help guide your buying journey.

Real Experiences Customer Feedback Many customers emphasize the significance of understanding the specific needs of your project when selecting a 1/8 wire mesh screen. User reviews often highlight the ease of working with stainless steel screens, praising their ability to maintain structural integrity under weight and environmental stress. Conversely, for projects with budget constraints, galvanized screens receive favorable feedback for their practicality and sufficient performance. A recurring theme in user experiences is the importance of precise measurements. Ensuring the mesh meets exact size requirements can greatly influence the outcome of its intended application. Customers often recommend purchasing from reputable suppliers who provide detailed product specifications and excellent customer service. Trustworthiness and Certifications To ensure trustworthiness, consider purchasing from manufacturers and suppliers who adhere to industry standards and certifications. Look for companies with ISO certification or compliance with ASTM specifications, which underscore a commitment to quality and safety. Reputable suppliers should provide detailed product descriptions, tensile strength data, and customer reviews. Why Size Matters The 1/8 specification indicates the mesh’s ability to balance permeability and filtration efficiently. In practical applications like filtration, the right mesh size ensures that particles of specific sizes can be effectively separated without impeding the flow of materials. In artistry and design, this mesh size can offer unique aesthetic properties, creating intricate patterns and structures. Ultimately, choosing the correct 1/8 wire mesh screen requires a well-rounded understanding of its applications, materials, and the specific demands of your project. Equipped with expert knowledge and the insights of experienced users, your purchase will stand on a foundation of quality and reliability. Whether it's for industrial, agricultural, or artistic purposes, making a knowledgeable choice will optimize performance and ensure lasting satisfaction.

Real Experiences Customer Feedback Many customers emphasize the significance of understanding the specific needs of your project when selecting a 1/8 wire mesh screen. User reviews often highlight the ease of working with stainless steel screens, praising their ability to maintain structural integrity under weight and environmental stress. Conversely, for projects with budget constraints, galvanized screens receive favorable feedback for their practicality and sufficient performance. A recurring theme in user experiences is the importance of precise measurements. Ensuring the mesh meets exact size requirements can greatly influence the outcome of its intended application. Customers often recommend purchasing from reputable suppliers who provide detailed product specifications and excellent customer service. Trustworthiness and Certifications To ensure trustworthiness, consider purchasing from manufacturers and suppliers who adhere to industry standards and certifications. Look for companies with ISO certification or compliance with ASTM specifications, which underscore a commitment to quality and safety. Reputable suppliers should provide detailed product descriptions, tensile strength data, and customer reviews. Why Size Matters The 1/8 specification indicates the mesh’s ability to balance permeability and filtration efficiently. In practical applications like filtration, the right mesh size ensures that particles of specific sizes can be effectively separated without impeding the flow of materials. In artistry and design, this mesh size can offer unique aesthetic properties, creating intricate patterns and structures. Ultimately, choosing the correct 1/8 wire mesh screen requires a well-rounded understanding of its applications, materials, and the specific demands of your project. Equipped with expert knowledge and the insights of experienced users, your purchase will stand on a foundation of quality and reliability. Whether it's for industrial, agricultural, or artistic purposes, making a knowledgeable choice will optimize performance and ensure lasting satisfaction.

share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025

-

Premium Stainless Steel Weave Mesh for Filtration and Security

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Safety & Durability

NewsJul.29,2025