Jan . 20, 2025 00:23 Back to list

buy 2 mm mesh screen

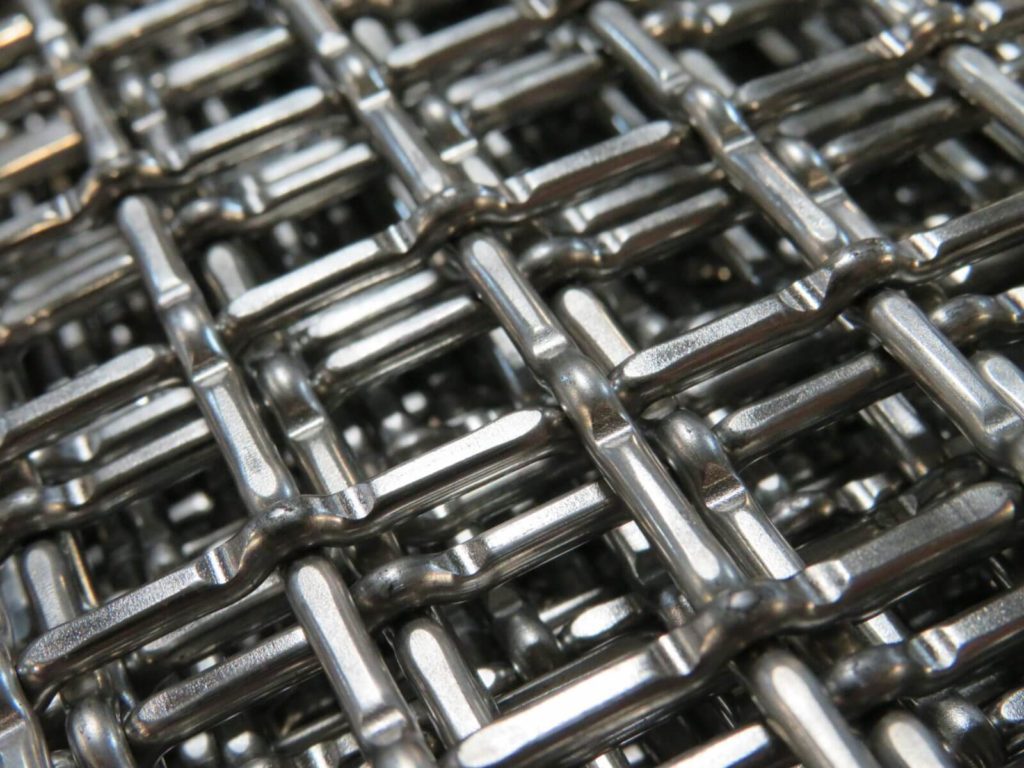

When it comes to selecting the right 2 mm mesh screen for your specific needs, understanding the unique characteristics and benefits of this material is crucial. The demand for mesh screens cannot be understated, especially for industries requiring precise filtration and separation.

The medical and pharmaceutical industries demand the utmost precision and consistency, making 2 mm mesh screens irreplaceable. These screens are used to ensure that products meet strict health and safety regulations by filtering out contaminants that could compromise product integrity. Their application extends to the manufacturing of drugs, where they help in achieving the desired consistencies of powders and granules. When purchasing a 2 mm mesh screen, it's essential to consider the material's quality and the specific requirements of your application. Opting for a reputable supplier is critical—a specialized vendor not only offers quality assurance but also professional guidance in selecting the right product. Their expertise can assist you in finding a mesh screen that balances functionality with cost-effectiveness. A reliable supplier will offer screens tested for tensile strength and abrasion resistance, factors that contribute to a product's longevity and efficacy. Moreover, understanding the compliance standards of different regions is crucial when sourcing these materials, especially for international operations. Trustworthy vendors are knowledgeable about such standards and can provide products that adhere to them, ensuring smooth operational transitions across territories. Investing in a 2 mm mesh screen is a decision best backed by research and consultation with experts. The collaboration with qualified professionals not only enhances the efficiency of application but also augments the overall operational quality. Prioritizing supplier expertise and material quality affirms the choice of the right mesh screen for your needs, reflective in improved outputs and safety standards. As technology advances, so do the capabilities and applications of mesh screens. Future developments may reveal even more innovative uses and materials, consistently pushing the bounds of what is achievable. Trusting knowledgeable industry leaders and investing in quality materials will always remain a cornerstone in making the most out of mesh screen applications.

The medical and pharmaceutical industries demand the utmost precision and consistency, making 2 mm mesh screens irreplaceable. These screens are used to ensure that products meet strict health and safety regulations by filtering out contaminants that could compromise product integrity. Their application extends to the manufacturing of drugs, where they help in achieving the desired consistencies of powders and granules. When purchasing a 2 mm mesh screen, it's essential to consider the material's quality and the specific requirements of your application. Opting for a reputable supplier is critical—a specialized vendor not only offers quality assurance but also professional guidance in selecting the right product. Their expertise can assist you in finding a mesh screen that balances functionality with cost-effectiveness. A reliable supplier will offer screens tested for tensile strength and abrasion resistance, factors that contribute to a product's longevity and efficacy. Moreover, understanding the compliance standards of different regions is crucial when sourcing these materials, especially for international operations. Trustworthy vendors are knowledgeable about such standards and can provide products that adhere to them, ensuring smooth operational transitions across territories. Investing in a 2 mm mesh screen is a decision best backed by research and consultation with experts. The collaboration with qualified professionals not only enhances the efficiency of application but also augments the overall operational quality. Prioritizing supplier expertise and material quality affirms the choice of the right mesh screen for your needs, reflective in improved outputs and safety standards. As technology advances, so do the capabilities and applications of mesh screens. Future developments may reveal even more innovative uses and materials, consistently pushing the bounds of what is achievable. Trusting knowledgeable industry leaders and investing in quality materials will always remain a cornerstone in making the most out of mesh screen applications.

share

Next:

Latest news

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025