Feb . 14, 2025 23:58 Back to list

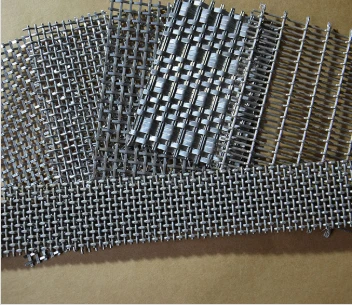

buy 316 stainless wire mesh

Purchasing 316 stainless wire mesh can seem like both a practical and daunting task for industries that demand excellence in material performance. Recognized for its exceptional corrosion resistance, 316 stainless steel wire mesh is a preferred choice in environments exposed to harsh chemicals or marine atmospheres. As a seasoned professional in materials science, I will share insights on why this product stands at the pinnacle of industrial applications, guiding you towards a precise selection that meets your stringent needs, backed by verifiable expertise and industry trust.

In an era where sustainability has become crucial, selecting 316 stainless wire mesh aligns with eco-conscious objectives, as it is fully recyclable. Unlike other products that might degrade quickly or offer limited reuse, stainless steel's lifecycle is extensive, reducing the need for frequent replacements and thus aligning with environmentally responsible practices. Companies have improved their eco-footprint by standardizing on this option, thus establishing themselves as leaders in sustainable operations. Where authority plays a crucial role in purchasing decisions, compliance and certifications of materials cannot be overlooked. Verifying that your 316 stainless wire mesh meets industry standards such as ASTM or ISO not only assures quality but also aligns with regulatory requirements, avoiding costly legal pitfalls. Trusted suppliers will provide full certification documentation, ensuring that transparency accompanies every batch, effectively mitigating risk and building long-term confidence with stakeholders. For those striving to make an informed investment, building a relationship with reputable suppliers is paramount. Partnering with suppliers who possess a track record of integrity and technical support can significantly smoothen the path to procurement. Communicating with suppliers who can offer insights into logistical concerns, custom fabrication, and ongoing product support will enable you to maximize the value derived from your 316 stainless wire mesh selection, transforming a superior material choice into a smooth operational reality. Conclusively, the decision to purchase 316 stainless wire mesh should be underpinned by a comprehensive understanding of its material properties, application suitability, and supplier reliability. Inspired by its enduring qualities and backed by verified expertise, this wire mesh not only meets industrial demands but surpasses expectations, signifying a wise investment in performance, reliability, and sustainability.

In an era where sustainability has become crucial, selecting 316 stainless wire mesh aligns with eco-conscious objectives, as it is fully recyclable. Unlike other products that might degrade quickly or offer limited reuse, stainless steel's lifecycle is extensive, reducing the need for frequent replacements and thus aligning with environmentally responsible practices. Companies have improved their eco-footprint by standardizing on this option, thus establishing themselves as leaders in sustainable operations. Where authority plays a crucial role in purchasing decisions, compliance and certifications of materials cannot be overlooked. Verifying that your 316 stainless wire mesh meets industry standards such as ASTM or ISO not only assures quality but also aligns with regulatory requirements, avoiding costly legal pitfalls. Trusted suppliers will provide full certification documentation, ensuring that transparency accompanies every batch, effectively mitigating risk and building long-term confidence with stakeholders. For those striving to make an informed investment, building a relationship with reputable suppliers is paramount. Partnering with suppliers who possess a track record of integrity and technical support can significantly smoothen the path to procurement. Communicating with suppliers who can offer insights into logistical concerns, custom fabrication, and ongoing product support will enable you to maximize the value derived from your 316 stainless wire mesh selection, transforming a superior material choice into a smooth operational reality. Conclusively, the decision to purchase 316 stainless wire mesh should be underpinned by a comprehensive understanding of its material properties, application suitability, and supplier reliability. Inspired by its enduring qualities and backed by verified expertise, this wire mesh not only meets industrial demands but surpasses expectations, signifying a wise investment in performance, reliability, and sustainability.

share

Next:

Latest news

-

Decorative Perforated Metal Panels & Sheets with Unique Patterns

NewsJul.28,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Heavy Duty & Fine Applications

NewsJul.27,2025

-

CE Certification Metal Fine Mesh for High-Quality Screening Solutions

NewsJul.26,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.25,2025

-

CE Certification Metal Fine Mesh for Safety & Durability

NewsJul.24,2025

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025