Jan . 21, 2025 04:50 Back to list

Woven Wire Drapery

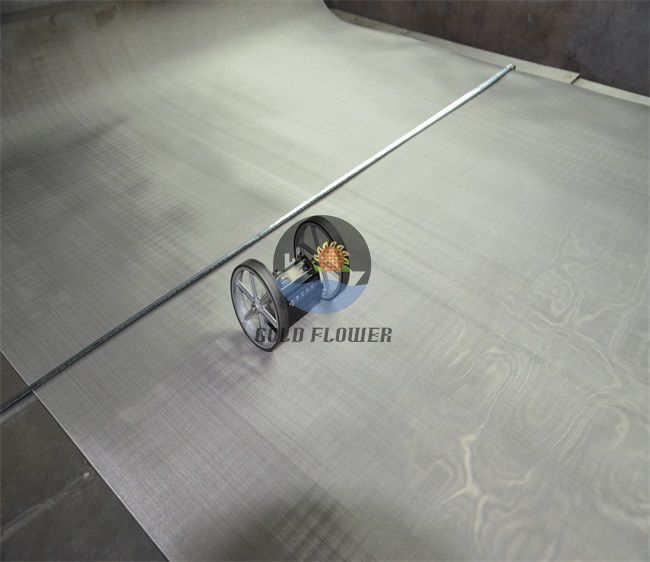

When it comes to selecting the right material for industrial applications, aluminium alloy wire mesh stands out due to its unique combination of properties that delivers unparalleled performance, durability, and versatility. This exceptional product is a preference across various sectors, thanks to several key factors shaped by years of material science advancements and profound industrial experiences.

Authoritativeness in the aluminium alloy wire mesh market is bolstered by rigorous testing and standardization. Products are subject to stringent ASTM and ISO standards, ensuring customers receive material compliant with global safety and quality benchmarks. This adherence to internationally recognized criteria provides users with confidence in the mesh’s performance and longevity, facilitating smoother procurement and integration processes. The availability of detailed certification further strengthens buyer trust and assists engineers in making informed material choices. Trustworthiness is augmented by an established track record of aluminium alloy mesh performance across diverse implementations. End users, ranging from construction professionals to home renovation experts, share countless successful experiences of using these meshes. Whether it's reinforcing structures, serving as a component in filtration systems, or providing security barriers, aluminium alloy wire mesh consistently meets user needs efficiently and effectively. Customer reviews and empirical usage data highlight not only the product’s versatility but also the satisfaction levels it garners in the field. In essence, buying aluminium alloy wire mesh is a decision backed by solid experience, expert technological processing, authoritative quality restraint, and trustworthy service history. This makes it an ideal choice for those seeking a material that delivers exceptional performance, reliability, and value across a multitude of applications. Combining these strengths opens up a realm of possibilities for its application, assured by its proven record and continuous development.

Authoritativeness in the aluminium alloy wire mesh market is bolstered by rigorous testing and standardization. Products are subject to stringent ASTM and ISO standards, ensuring customers receive material compliant with global safety and quality benchmarks. This adherence to internationally recognized criteria provides users with confidence in the mesh’s performance and longevity, facilitating smoother procurement and integration processes. The availability of detailed certification further strengthens buyer trust and assists engineers in making informed material choices. Trustworthiness is augmented by an established track record of aluminium alloy mesh performance across diverse implementations. End users, ranging from construction professionals to home renovation experts, share countless successful experiences of using these meshes. Whether it's reinforcing structures, serving as a component in filtration systems, or providing security barriers, aluminium alloy wire mesh consistently meets user needs efficiently and effectively. Customer reviews and empirical usage data highlight not only the product’s versatility but also the satisfaction levels it garners in the field. In essence, buying aluminium alloy wire mesh is a decision backed by solid experience, expert technological processing, authoritative quality restraint, and trustworthy service history. This makes it an ideal choice for those seeking a material that delivers exceptional performance, reliability, and value across a multitude of applications. Combining these strengths opens up a realm of possibilities for its application, assured by its proven record and continuous development.

share

Next:

Latest news

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025