Jan . 14, 2025 10:00 Back to list

buy metal woven wire mesh

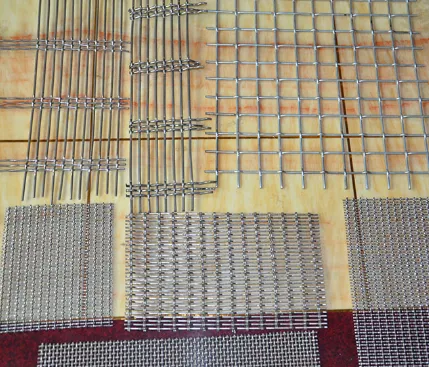

When it comes to sourcing a metal woven wire mesh, the decision for any buyer, whether a small DIY enthusiast or a large industrial contractor, hinges on quality, durability, and adaptability to various uses. A product class that is sometimes underestimated, woven wire mesh serves multiple industries and shows a remarkable versatility that makes it indispensable.

Be wary of low-cost alternatives that often compromise on these nuanced manufacturing techniques, resulting in inferior products. Trust in manufacturers that wield significant industry experience and hold certifications such as ISO or ASTM compliance. These accolades provide an authoritative guarantee that their products adhere to globally recognized quality standards, ensuring reliability and safety in their application. Authoritativeness in the realm of metal woven wire mesh is further exhibited by the presence of rigorous testing procedures. Legitimate suppliers conduct comprehensive tensile testing, mesh count verification, and corrosion resistance tests. Transparency in sharing these results can significantly enhance trustworthiness, reassuring buyers of the product’s quality profile. For those delving into large-scale projects, assessing case studies or reaching out to client testimonials of previous large-scale installations can provide indirect experience insights. Understanding how a particular mesh performed under variable conditions can be crucial in making an informed decision, highlighting potential strengths or weaknesses not immediately obvious during purchase. The journey to buy the right metal woven wire mesh is one underlined by the product's application, the expertise of the supplier, and the trust established through quality assurance. Aligning these factors ensures your project not only meets its functional needs but is emboldened by materials that withstand the rigors of their intended use. Quality woven mesh is more than a simple product; it is a cornerstone of robust design, dependable operational systems, and long-term reliability.

Be wary of low-cost alternatives that often compromise on these nuanced manufacturing techniques, resulting in inferior products. Trust in manufacturers that wield significant industry experience and hold certifications such as ISO or ASTM compliance. These accolades provide an authoritative guarantee that their products adhere to globally recognized quality standards, ensuring reliability and safety in their application. Authoritativeness in the realm of metal woven wire mesh is further exhibited by the presence of rigorous testing procedures. Legitimate suppliers conduct comprehensive tensile testing, mesh count verification, and corrosion resistance tests. Transparency in sharing these results can significantly enhance trustworthiness, reassuring buyers of the product’s quality profile. For those delving into large-scale projects, assessing case studies or reaching out to client testimonials of previous large-scale installations can provide indirect experience insights. Understanding how a particular mesh performed under variable conditions can be crucial in making an informed decision, highlighting potential strengths or weaknesses not immediately obvious during purchase. The journey to buy the right metal woven wire mesh is one underlined by the product's application, the expertise of the supplier, and the trust established through quality assurance. Aligning these factors ensures your project not only meets its functional needs but is emboldened by materials that withstand the rigors of their intended use. Quality woven mesh is more than a simple product; it is a cornerstone of robust design, dependable operational systems, and long-term reliability.

share

Next:

Latest news

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025