Feb . 06, 2025 01:42 Back to list

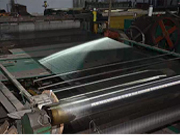

buy model wire mesh

The demand for model wire mesh has significantly increased, especially in industries where precision and reliability are paramount. Understanding the importance of quality when purchasing model wire mesh can greatly affect the results and efficiency in various applications.

Furthermore, understanding the supplier’s reputation and expertise in the field is crucial. Opt for manufacturers and suppliers that have a proven track record for delivering high-quality products. It’s advantageous to seek companies that offer warranties or satisfaction guarantees, as these policies often reflect the supplier’s confidence in their product. Networking with other professionals in the industry can also be beneficial. Sharing experiences and recommendations can provide valuable insights into the reliability and performance of various wire mesh products. Similarly, reading reviews and case studies online can offer practical perspectives on real-life applications of the wire mesh, further aiding in making an informed purchasing decision. Price is always a significant consideration, but it should not compromise the mesh's quality and suitability for its intended purpose. While cheaper options may be appealing financially, they can result in higher long-term costs due to replacements or inefficiencies. Balancing cost with quality is key to ensuring that projects remain within budget without sacrificing integrity or performance. In conclusion, when buying model wire mesh, it’s imperative to thoroughly consider material type, mesh size, weave pattern, supplier expertise, and the quality assurance processes in place. Leveraging these considerations ensures that you invest in a product that not only meets but exceeds the specific requirements of your application. By prioritizing these factors, you'll be better equipped to choose a wire mesh that offers durability, efficiency, and reliability—essentials for any successful project.

Furthermore, understanding the supplier’s reputation and expertise in the field is crucial. Opt for manufacturers and suppliers that have a proven track record for delivering high-quality products. It’s advantageous to seek companies that offer warranties or satisfaction guarantees, as these policies often reflect the supplier’s confidence in their product. Networking with other professionals in the industry can also be beneficial. Sharing experiences and recommendations can provide valuable insights into the reliability and performance of various wire mesh products. Similarly, reading reviews and case studies online can offer practical perspectives on real-life applications of the wire mesh, further aiding in making an informed purchasing decision. Price is always a significant consideration, but it should not compromise the mesh's quality and suitability for its intended purpose. While cheaper options may be appealing financially, they can result in higher long-term costs due to replacements or inefficiencies. Balancing cost with quality is key to ensuring that projects remain within budget without sacrificing integrity or performance. In conclusion, when buying model wire mesh, it’s imperative to thoroughly consider material type, mesh size, weave pattern, supplier expertise, and the quality assurance processes in place. Leveraging these considerations ensures that you invest in a product that not only meets but exceeds the specific requirements of your application. By prioritizing these factors, you'll be better equipped to choose a wire mesh that offers durability, efficiency, and reliability—essentials for any successful project.

share

Latest news

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025