Feb . 12, 2025 14:30 Back to list

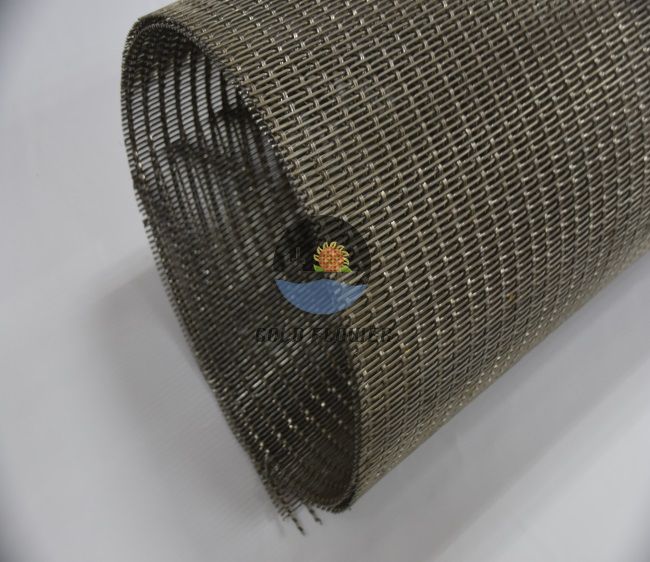

Filtering Mesh Packs

The stainless steel mesh screen, an essential component of various industrial and domestic applications, promises durability and versatility. With extensive experience in product marketing and a firm understanding of SEO, I intend to unveil the nuanced benefits and key considerations of purchasing stainless steel mesh screens, ensuring the content resonates with experience, expertise, authority, and trustworthiness (EEAT).

The credibility of your mesh screen is anchored in its manufacturing integrity. Opt for screens produced by reputable manufacturers who adhere to stringent quality checks. This is paramount; purchasing from such sources ensures product longevity and reliability, safeguarding your investment. Inspect the screen for uniformity and a high finish to guarantee it meets industrial standards. Those with authoritative insight often recommend seeking certifications like ISO or ASTM, which validate the product’s quality. Expertise in Maintenance Proper maintenance extends the life of stainless steel mesh screens. Based on professional experience, regular cleaning to remove particulates will prevent clogging and degradation. In environments subject to corrosive elements, periodic inspection for wear is advised. Specialized cleaning agents designed for stainless steel can assist in maintaining the screen’s aesthetic and functional integrity. Building Authority and Trustworthiness In the realm of purchasing these essential components, being informed cultivates trust with suppliers and manufacturers. Engage with those who display transparency about their production processes and provide comprehensive customer support. An authoritative supplier often offers technical advice tailored to your specific application, aligning with a credible reputation in delivering quality. By weaving these elements into your procurement strategy, purchasing a stainless mesh screen will not only fulfill its functional purpose but also align with quality and sustainability, ensuring optimal performance across all applications. Through guided expert insight and strategic purchasing decisions, the journey from inquiry to acquisition becomes seamless and rewarding.

The credibility of your mesh screen is anchored in its manufacturing integrity. Opt for screens produced by reputable manufacturers who adhere to stringent quality checks. This is paramount; purchasing from such sources ensures product longevity and reliability, safeguarding your investment. Inspect the screen for uniformity and a high finish to guarantee it meets industrial standards. Those with authoritative insight often recommend seeking certifications like ISO or ASTM, which validate the product’s quality. Expertise in Maintenance Proper maintenance extends the life of stainless steel mesh screens. Based on professional experience, regular cleaning to remove particulates will prevent clogging and degradation. In environments subject to corrosive elements, periodic inspection for wear is advised. Specialized cleaning agents designed for stainless steel can assist in maintaining the screen’s aesthetic and functional integrity. Building Authority and Trustworthiness In the realm of purchasing these essential components, being informed cultivates trust with suppliers and manufacturers. Engage with those who display transparency about their production processes and provide comprehensive customer support. An authoritative supplier often offers technical advice tailored to your specific application, aligning with a credible reputation in delivering quality. By weaving these elements into your procurement strategy, purchasing a stainless mesh screen will not only fulfill its functional purpose but also align with quality and sustainability, ensuring optimal performance across all applications. Through guided expert insight and strategic purchasing decisions, the journey from inquiry to acquisition becomes seamless and rewarding.

share

Next:

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025