Feb . 14, 2025 15:12 Back to list

ce certification buy wire mesh fence

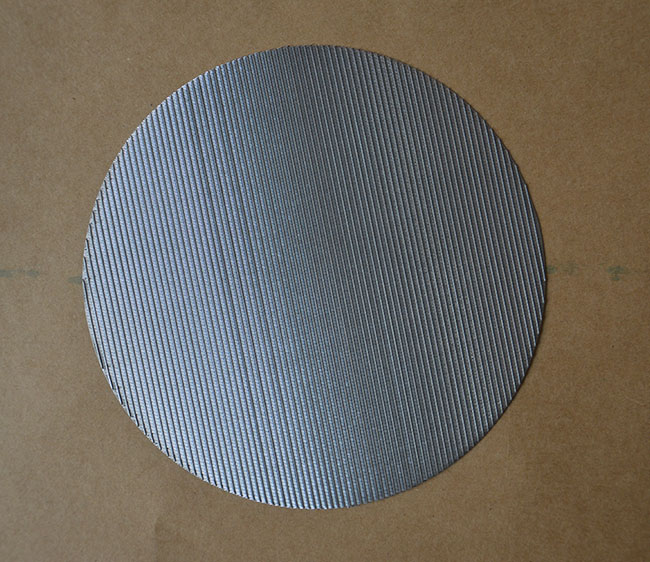

The art of weaving mesh is an age-old craft that has seamlessly adapted into modern industrial applications. From construction to design, weaving mesh plays a crucial role, blending functionality with aesthetics. For businesses and individuals looking to buy weaving mesh, finding the right product that combines quality, durability, and cost-effectiveness is essential. This comprehensive guide delves into the intricacies of purchasing weaving mesh, focusing on experience, expertise, authoritativeness, and trustworthiness—the four pillars crucial for making an informed decision.

Many companies have shared success stories about how weaving mesh has enhanced their operations. For instance, an agricultural business detailed how switching to high-quality stainless steel mesh improved their grain sorting efficiency and reduced equipment downtime significantly. Such real-world testimonials not only reinforce the benefits of investing in quality products but also serve as guidance for prospective buyers. Building Authority Through Expertise Companies and individuals should prioritize suppliers with deep industry knowledge, often evidenced by long-standing professional relationships and affiliations with industrial organizations. These suppliers not only possess the technical know-how but also stay updated on market trends and innovations, offering clients cutting-edge products and advice. The Role of Technological Advances Advancements in technology have opened new possibilities in weaving mesh production. Automated weaving technologies ensure greater precision and consistency, reflecting a supplier’s commitment to quality and innovation. Buyers should look for suppliers who leverage such advancements to provide superior products and services. The Importance of Trustworthiness Finally, trust in a supplier is built over time through transparency and accountability. Reliable vendors provide clear information regarding their products and policies, fostering a trustworthy relationship. Buyers should seek out suppliers who offer clear communication channels and are willing to address any customer concerns promptly and professionally. Conclusion Buying weaving mesh is not merely a transaction but a strategic decision that impacts the quality and success of the intended application. By focusing on experience, expertise, authoritativeness, and trustworthiness, buyers can ensure they choose the right product and supplier. As weaving mesh continues to evolve, aligning with trusted industry partners can provide the assurance needed for long-term success and satisfaction.

Many companies have shared success stories about how weaving mesh has enhanced their operations. For instance, an agricultural business detailed how switching to high-quality stainless steel mesh improved their grain sorting efficiency and reduced equipment downtime significantly. Such real-world testimonials not only reinforce the benefits of investing in quality products but also serve as guidance for prospective buyers. Building Authority Through Expertise Companies and individuals should prioritize suppliers with deep industry knowledge, often evidenced by long-standing professional relationships and affiliations with industrial organizations. These suppliers not only possess the technical know-how but also stay updated on market trends and innovations, offering clients cutting-edge products and advice. The Role of Technological Advances Advancements in technology have opened new possibilities in weaving mesh production. Automated weaving technologies ensure greater precision and consistency, reflecting a supplier’s commitment to quality and innovation. Buyers should look for suppliers who leverage such advancements to provide superior products and services. The Importance of Trustworthiness Finally, trust in a supplier is built over time through transparency and accountability. Reliable vendors provide clear information regarding their products and policies, fostering a trustworthy relationship. Buyers should seek out suppliers who offer clear communication channels and are willing to address any customer concerns promptly and professionally. Conclusion Buying weaving mesh is not merely a transaction but a strategic decision that impacts the quality and success of the intended application. By focusing on experience, expertise, authoritativeness, and trustworthiness, buyers can ensure they choose the right product and supplier. As weaving mesh continues to evolve, aligning with trusted industry partners can provide the assurance needed for long-term success and satisfaction.

share

Latest news

-

High-Efficiency Particle Filter for Superior Air Purification

NewsJul.23,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025