Feb . 15, 2025 18:37 Back to list

buy wire netting machine

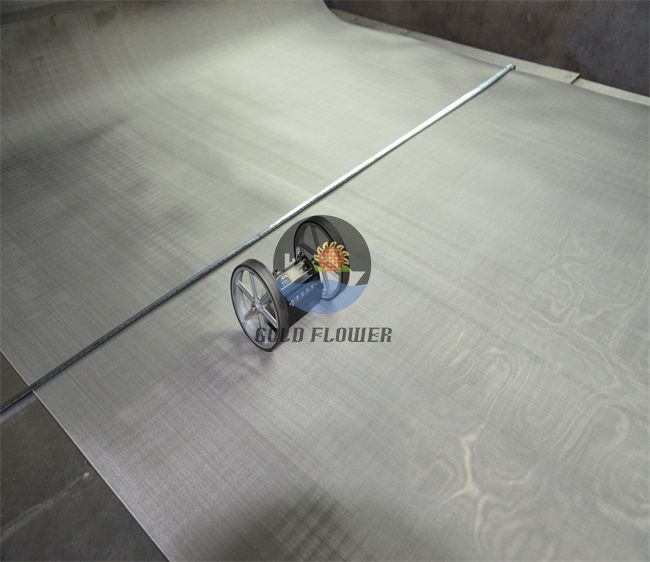

Searching for the ideal wire netting machine calls for a meticulous exploration of authentic experiences, insights from industry experts, authoritative guidance, and trust-building measures. As an essential component in a plethora of industries, the wire netting machine plays a pivotal role in producing durable fencing materials, protective nets, and reinforcement grids, among other products.

Authoritativeness in this domain is often demonstrated through certifications and endorsements from industry associations or governing bodies. A wire netting machine that carries compliance badges or has been recognized by authoritative industry organizations offers tangible evidence of its credibility and performance standards. Manufacturers' willingness to share detailed technical specifications and provide transparent operational data further underscores their authoritative standing. Prospective buyers can derive significant confidence from knowing that their chosen machine has undergone rigorous testing and meets established industry benchmarks. Trustworthiness is paramount when selecting any machinery, especially those integral to manufacturing operations. Reputable suppliers and manufacturers typically guarantee their machines through comprehensive warranties and reliable customer support mechanisms. Testimonials and case studies from verified customers often provide compelling narratives that highlight a brand's commitment to quality and customer satisfaction. Establishing trust also involves scrutinizing the after-sales services, such as the availability of spare parts, the efficiency of repair services, and the promptness of technical support teams. These facets demonstrate a manufacturer's commitment not only to selling a product but to offering a holistic service that empowers customers over the machine's lifecycle. In conclusion, the journey to finding the perfect wire netting machine encompasses a blend of experiential insights, expert-led assessments, authoritative validations, and trust-enforcing measures. By focusing on these dimensions, potential buyers are better equipped to make informed decisions, ensuring their investment translates into operational efficiency, product quality, and enhanced productivity. This comprehensive approach reduces risks and fortifies the buyer's assurance in their selection, promising long-term value and satisfaction.

Authoritativeness in this domain is often demonstrated through certifications and endorsements from industry associations or governing bodies. A wire netting machine that carries compliance badges or has been recognized by authoritative industry organizations offers tangible evidence of its credibility and performance standards. Manufacturers' willingness to share detailed technical specifications and provide transparent operational data further underscores their authoritative standing. Prospective buyers can derive significant confidence from knowing that their chosen machine has undergone rigorous testing and meets established industry benchmarks. Trustworthiness is paramount when selecting any machinery, especially those integral to manufacturing operations. Reputable suppliers and manufacturers typically guarantee their machines through comprehensive warranties and reliable customer support mechanisms. Testimonials and case studies from verified customers often provide compelling narratives that highlight a brand's commitment to quality and customer satisfaction. Establishing trust also involves scrutinizing the after-sales services, such as the availability of spare parts, the efficiency of repair services, and the promptness of technical support teams. These facets demonstrate a manufacturer's commitment not only to selling a product but to offering a holistic service that empowers customers over the machine's lifecycle. In conclusion, the journey to finding the perfect wire netting machine encompasses a blend of experiential insights, expert-led assessments, authoritative validations, and trust-enforcing measures. By focusing on these dimensions, potential buyers are better equipped to make informed decisions, ensuring their investment translates into operational efficiency, product quality, and enhanced productivity. This comprehensive approach reduces risks and fortifies the buyer's assurance in their selection, promising long-term value and satisfaction.

share

Next:

Latest news

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025