Feb . 14, 2025 16:13 Back to list

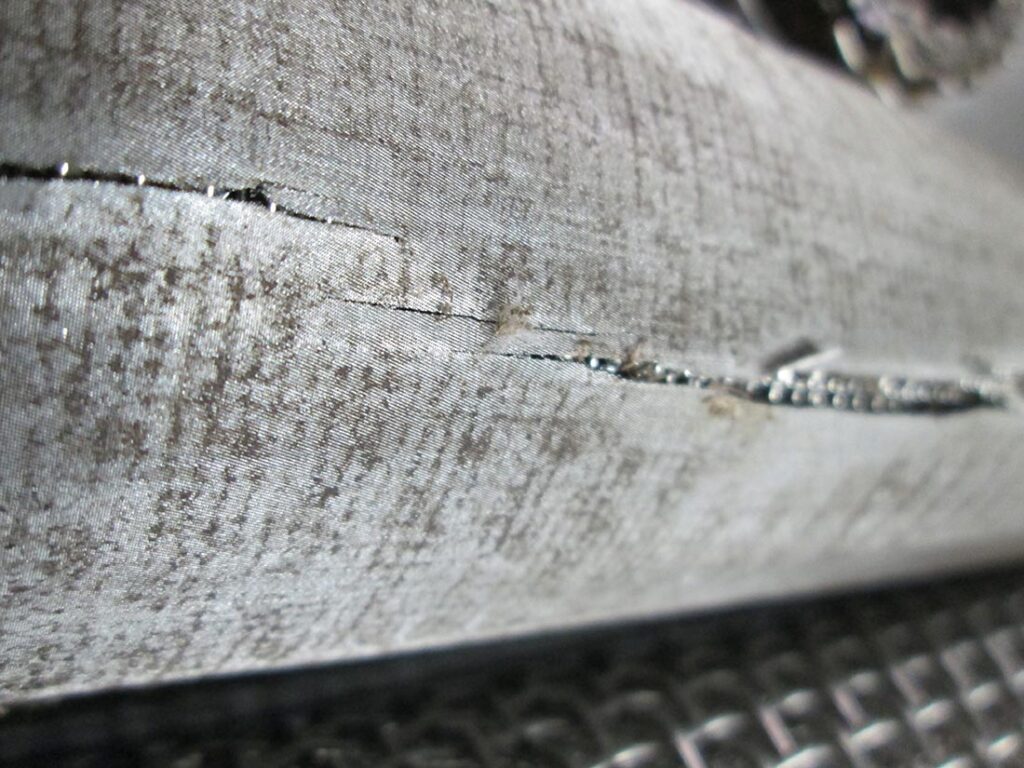

woven wire mesh filter

Exploring the world of woven metal wire products offers a glimpse into a niche yet booming industry brimming with versatility and utility. Used across myriad sectors, woven metal wire combines the precision of engineering with the robustness of premium-grade materials. As businesses and hobbyists consider purchasing these products, an understanding of their applications, benefits, and considerations is essential for making informed decisions.

However, when purchasing woven metal wire, factors such as mesh count, weave type, and wire diameter are crucial considerations impacting performance and longevity. Mesh count refers to the number of openings per linear inch, influencing the mesh’s functionality depending on the intended application. Whether aiming for a filtration device requiring high precision or a decorative facade with specific aesthetic needs, understanding these attributes is key. The weave type—plain or twill, for example—determines factors such as strength and transparency, and selecting the appropriate type plays a significant role in meeting user needs. A trustworthy provider will also carry certifications attesting to the quality of the manufacturing process and material sourcing. These certifications ensure that the woven wire meets industry standards for safety and effectiveness, offering assurance to even the most discerning clients. Consulting with qualified professionals can further aid in navigating these choices, as they bring both authority and experience to the conversation, ensuring that the selection aligns with the application’s demands. Emphasizing the importance of trustworthiness, stakeholders in industries utilizing woven metal wire must prioritize suppliers who offer transparency in their operations. Comprehensive documentation, detailed product specifications, and exemplary customer service are all signs of a reputable company. Such companies not only deliver high-quality products but also cultivate lasting partnerships by educating their clients on optimal product use and maintenance, enhancing value and satisfaction. Ultimately, buying woven metal wire is not merely a transactional decision but a strategic investment. It requires careful consideration woven with informed insight into the product’s capabilities and applications. Whether for industrial, commercial, or architectural use, harnessing the full potential of woven metal wire ensures efficiency, design excellence, and long-term satisfaction for any ambitious project.

However, when purchasing woven metal wire, factors such as mesh count, weave type, and wire diameter are crucial considerations impacting performance and longevity. Mesh count refers to the number of openings per linear inch, influencing the mesh’s functionality depending on the intended application. Whether aiming for a filtration device requiring high precision or a decorative facade with specific aesthetic needs, understanding these attributes is key. The weave type—plain or twill, for example—determines factors such as strength and transparency, and selecting the appropriate type plays a significant role in meeting user needs. A trustworthy provider will also carry certifications attesting to the quality of the manufacturing process and material sourcing. These certifications ensure that the woven wire meets industry standards for safety and effectiveness, offering assurance to even the most discerning clients. Consulting with qualified professionals can further aid in navigating these choices, as they bring both authority and experience to the conversation, ensuring that the selection aligns with the application’s demands. Emphasizing the importance of trustworthiness, stakeholders in industries utilizing woven metal wire must prioritize suppliers who offer transparency in their operations. Comprehensive documentation, detailed product specifications, and exemplary customer service are all signs of a reputable company. Such companies not only deliver high-quality products but also cultivate lasting partnerships by educating their clients on optimal product use and maintenance, enhancing value and satisfaction. Ultimately, buying woven metal wire is not merely a transactional decision but a strategic investment. It requires careful consideration woven with informed insight into the product’s capabilities and applications. Whether for industrial, commercial, or architectural use, harnessing the full potential of woven metal wire ensures efficiency, design excellence, and long-term satisfaction for any ambitious project.

share

Latest news

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.22,2025

-

CE Certified 250 Micron Stain Steel Mesh - Durable & Safe

NewsJul.21,2025

-

CE Certified 250 Micron Stainless Steel Mesh - High Durability & CE Approved

NewsJul.21,2025

-

Premium Slope Collapse Protection Mesh | Durable & Effective

NewsJul.20,2025

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025