Aug . 13, 2024 13:24 Back to list

CE Certification for Spot Welded Wire Mesh Products Ensures Quality and Compliance for Industry Standards

CE Certification of Spot Welded Wire Mesh

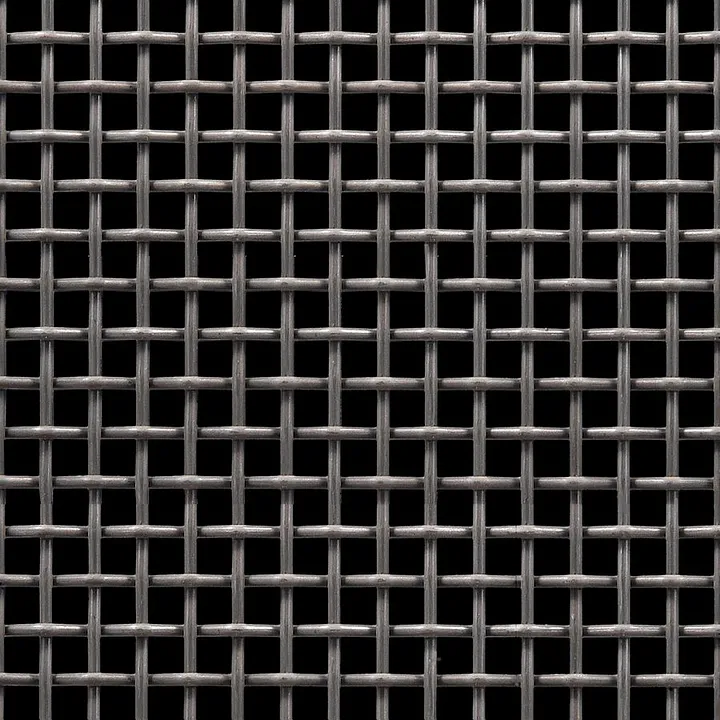

Spot welded wire mesh is a versatile and widely used material in various industrial applications, including construction, automotive, agriculture, and fencing. The unique characteristics of this mesh, created by heavily welding intersecting wires at specific spots, result in a strong, durable, and reliable product. However, to ensure the quality and safety standards of spot welded wire mesh, it is essential to obtain CE certification. This article delves into the importance of CE certification for spot welded wire mesh and its implications for manufacturers and end-users.

What is CE Certification?

CE certification, or Conformité Européenne, is a mandatory conformity mark for products sold within the European Economic Area (EEA). It indicates that a product meets the essential health, safety, and environmental requirements set forth by EU legislation. For manufacturers, obtaining CE certification is not just a legal requirement but also a mark of quality assurance. It assures customers that the products have undergone rigorous testing and adhere to the highest safety standards.

Why is CE Certification Important for Spot Welded Wire Mesh?

1. Quality Assurance The CE mark signifies that the spot welded wire mesh has been tested and meets the necessary quality standards. This certification is crucial, especially in industries such as construction and automotive, where safety and reliability are paramount.

2. Market Access CE certification allows manufacturers to sell their products within the EEA without facing unnecessary barriers. Without this certification, companies may find their products restricted or banned from entering the European market, limiting their potential customer base.

3. Consumer Trust For end-users, purchasing CE certified spot welded wire mesh provides peace of mind. They can trust that the product they are using has been evaluated for safety and efficacy, reducing the likelihood of accidents or failures due to subpar materials.

4. Legal Compliance By obtaining CE certification, manufacturers ensure compliance with European directives and regulations. This not only minimizes the risk of legal repercussions but also enhances the reputation of the company as a responsible manufacturer.

ce certification spot welded wire mesh

The Certification Process

Obtaining CE certification for spot welded wire mesh involves several steps

1. Assessment of Applicable Directives The manufacturer must determine which EU directives are relevant to their product. For spot welded wire mesh, this may include the Low Voltage Directive, the Machinery Directive, or the Construction Products Regulation.

2. Testing and Inspection The product must undergo thorough testing and inspection by an authorized body to assess compliance with the relevant standards.

3. Technical Documentation Manufacturers must compile technical documentation, including test results, manufacturing processes, and quality control measures. This documentation demonstrates compliance with the applicable directives.

4. Declaration of Conformity After successfully passing the assessment, the manufacturer must prepare a Declaration of Conformity, stating that the product adheres to all relevant EU legislation. This document must be retained for at least ten years following the last product placed on the market.

5. Affixing the CE Mark Once certified, the manufacturer can affix the CE mark to their spot welded wire mesh, signifying compliance with EU regulations.

Conclusion

CE certification is essential for manufacturers of spot welded wire mesh, ensuring that their products meet the necessary safety and quality standards required by the European market. For end-users, CE certification serves as a guarantee of product reliability, contributing to safer and more efficient use in various applications. With the growing importance of safety and quality in construction materials, CE certification will continue to be a critical aspect of the spot welded wire mesh industry in the years to come.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025