Nov . 19, 2024 17:16 Back to list

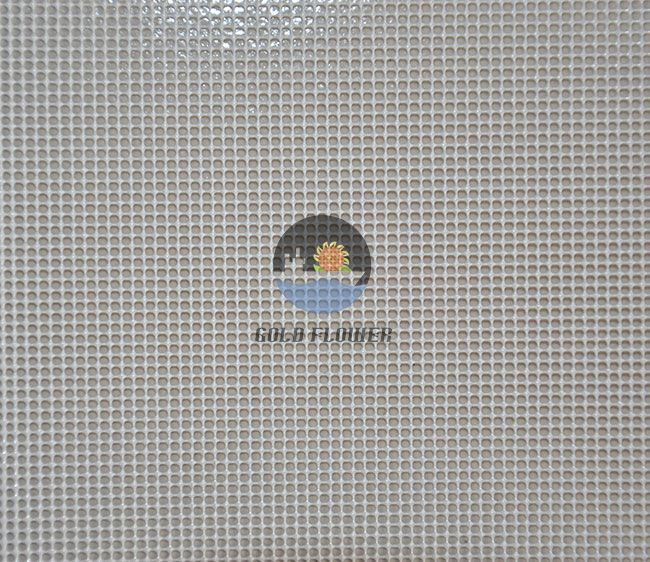

CE Certified Super Fine Metal Mesh for Enhanced Filtration and Durability

CE Certification for Super Fine Metal Mesh Ensuring Safety and Quality

In today’s highly competitive market, quality and safety standards are paramount for products used in various applications. One significant area that has gained attention in this context is super fine metal mesh. This material, known for its precise filtration capabilities and versatility, is widely utilized in industries ranging from aerospace to pharmaceuticals. To ensure that these materials meet the necessary safety and performance standards, obtaining CE certification has become crucial.

CE certification, which stands for Conformité Européenne, is a designation indicating that a product meets European health, safety, and environmental requirements. For super fine metal mesh, this certification is particularly important due to its application in sensitive environments. The mesh is often used in processes that require high levels of purification and filtration, such as in liquid and gas filtration systems.

The journey towards CE certification for super fine metal mesh involves several critical steps. First, manufacturers must conduct a comprehensive risk assessment to identify potential hazards associated with their products. This includes evaluating the materials used, the manufacturing process, and the intended application of the mesh. By understanding these factors, manufacturers can implement appropriate measures to mitigate risks and ensure compliance with EU standards.

ce certification super fine metal mesh

Next, manufacturers must adhere to relevant European directives that apply to their products. For super fine metal mesh, this might include directives related to machinery safety, personal protective equipment, and environmental impact. Each directive outlines essential requirements that must be adhered to for CE marking. This stage often involves rigorous testing and evaluation to demonstrate compliance with the applicable standards.

Once the necessary testing has been completed, manufacturers must compile a technical file that documents the entire process, including design, production, and testing protocols. This file serves as evidence of compliance and must be made available upon request by regulatory authorities. It is essential for manufacturers to maintain accurate records as these documents can be critical in the event of audits or inspections.

After successfully completing all these steps, manufacturers can affix the CE mark to their super fine metal mesh products. This mark not only signifies that the product meets EU standards but also enhances the marketability of the product across Europe, as customers are increasingly looking for assurance that the products they use are safe and reliable.

In conclusion, CE certification for super fine metal mesh is a vital process that ensures the product is safe, high-quality, and meets the stringent requirements of the European market. As industries continue to evolve and the demand for high-performance materials increases, achieving CE certification will be essential for manufacturers aiming to establish credibility and trust with consumers. By prioritizing safety and quality through CE certification, manufacturers can not only comply with regulatory requirements but also foster innovation and growth within their respective industries.

share

-

Screen Mesh Price Deals | gpt-4-turbo Optimized Pricing

NewsAug.01,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025

-

CE Certification Buy Wire Mesh Fence for High Security and Durability

NewsJul.30,2025

-

Stainless Steel Mesh Filter Discs for Precise Filtration Solutions

NewsJul.29,2025

-

CE Certification 250 Micron Stainless Steel Mesh for Industrial Use

NewsJul.29,2025