Oct . 20, 2024 12:33 Back to list

china stainless mesh

The Versatility of China Stainless Mesh Applications and Innovations

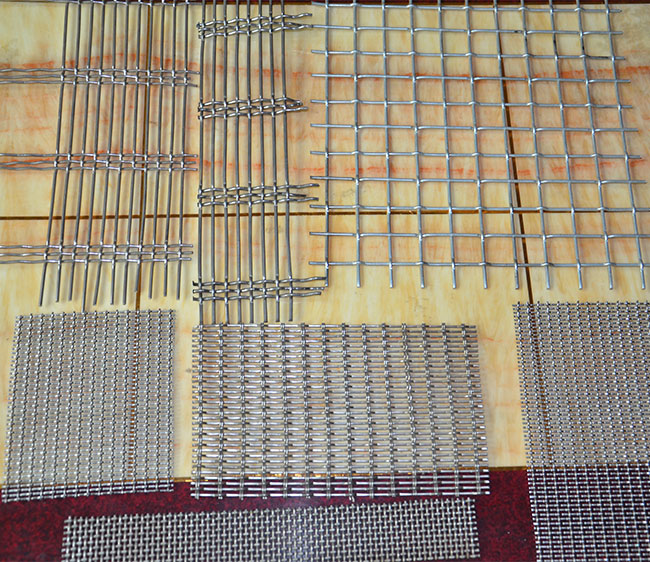

Stainless steel mesh, known for its durability and versatility, has become an essential material in various industries worldwide. In China, the production of stainless steel mesh has significantly increased, addressing the growing demand for high-quality filtering and support materials. This article delves into the characteristics, applications, and innovations surrounding China’s stainless mesh industry.

Characteristics of Stainless Mesh

Stainless steel mesh is crafted from high-grade stainless steel, which makes it resistant to corrosion, rust, and wear. This intrinsic strength ensures longevity, making the mesh suitable for both indoor and outdoor applications. The production process involves weaving fine wires into a grid-like structure, which can vary in both the diameter of the wire and the size of the openings. Consequently, this flexibility allows manufacturers to cater to diverse needs and specifications.

Moreover, stainless steel mesh is known for its high tensile strength, enabling it to endure a significant amount of stress without deforming. The material also exhibits excellent thermal stability, making it ideal for environments that experience substantial temperature fluctuations. These characteristics contribute to stainless steel mesh's popularity across various sectors, including construction, food processing, and pharmaceuticals.

Applications of Stainless Mesh in Different Industries

1. Construction and Architecture In the construction sector, stainless steel mesh serves multiple purposes, from being utilized as reinforcing material in concrete structures to decorative applications such as façades and railing systems. The mesh's aesthetic appeal alongside its strength ensures durability without compromising design.

2. Food and Beverage In food processing, stainless steel mesh is often used in filtration and sieving applications. It prevents contaminants from entering food products and is essential in processes like brewing, where finely sieved materials enhance product quality. Its easy-to-clean surface also complies with hygiene regulations, making it a preferred choice in this industry.

3. Chemical Engineering The chemical industry heavily relies on stainless steel mesh for heat exchangers and as a support medium for catalysts. Given that many chemicals can be aggressive or corrosive, the corrosion resistance of stainless steel makes it an ideal fit for these demanding applications.

china stainless mesh

4. Pharmaceuticals In pharmaceuticals, stainless steel mesh plays a vital role in ensuring product purity. It is often employed in filtration processes, helping to maintain the standards required in drug manufacturing.

5. Mining and Mineral Processing In the mining sector, stainless steel mesh is critical for sieving and separation processes. Its robustness can endure harsh environments, effectively processing materials while maintaining structural integrity.

6. Aerospace and Automotive Advanced stainless steel mesh is evolving for specialized applications within aerospace and automotive industries, where lightweight yet strong materials are pivotal. Components such as filtration systems and structural reinforcements benefit from these innovative applications.

Innovations in Stainless Mesh Technology

The stainless steel mesh industry in China is witnessing remarkable innovations aimed at improving performance and decreasing production costs. Advanced manufacturing techniques, including automated weaving and laser cutting, enable manufacturers to produce bespoke mesh solutions with precision.

Moreover, the development of nano-coatings has added an extra layer of protection against corrosion, extending the lifespan of stainless steel mesh even further. Research into different alloys and treatments is ongoing to enhance the mechanical properties of the mesh and broaden its functional capabilities.

Environmental sustainability is also becoming a focal point in the industry. Manufacturers are exploring ways to recycle stainless steel and minimize waste during production, aligning with global sustainability goals.

Conclusion

The stainless steel mesh industry in China is flourishing, driven by technological advancements and the diverse needs of various sectors. Its durability, resistance to corrosion, and versatility have made it a vital resource across multiple applications. As the demand for high-quality materials continues to rise, the innovations and improvements in stainless steel mesh technology will undoubtedly pave the way for further growth and adaptability in this essential field. With a focus on sustainability and performance, China is set to remain a leading player in the global stainless steel mesh market.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025