Aug . 17, 2024 13:25 Back to list

Custom OEM Dutch Wire Mesh Solutions for Industrial Applications and Filtration Needs

Exploring OEM Dutch Wire Mesh The Perfect Solution for Diverse Applications

In today's fast-paced industrial landscape, the demand for versatile and reliable filtration solutions has reached new heights. One such remarkable product that has garnered attention in various sectors is OEM Dutch wire mesh. This unique type of wire mesh combines fine mesh characteristics with a sturdy structure, making it an ideal choice for a range of applications, including filtration, separation, and reinforcement.

What is Dutch Wire Mesh?

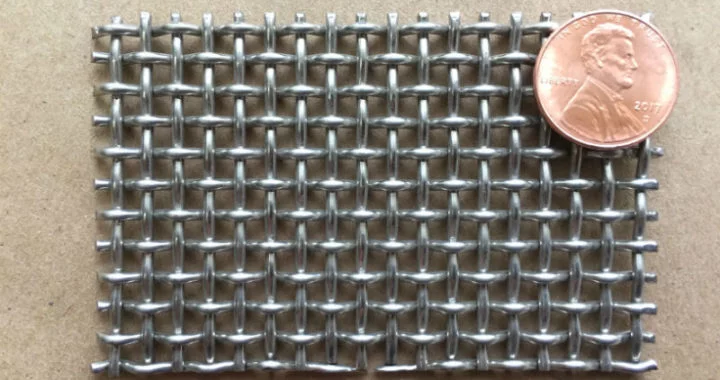

Dutch wire mesh, alternatively known as Dutch weave mesh, is distinctively characterized by its tight weave and different wire diameters. It typically features a coarse outer layer and a finer inner layer, creating a unique gradient structure that allows for controlled filtration. The mesh is constructed using high-quality stainless steel, which offers excellent resistance to corrosion, heat, and wear. This durability makes it perfect for demanding environments, such as chemical processing, food processing, and petrochemical industries.

The Benefits of OEM Dutch Wire Mesh

1. Customization One of the key advantages of OEM Dutch wire mesh is the ability to customize its specifications, including wire diameter, opening size, and material grade. This level of customization enables businesses to tailor the mesh to their specific needs. Whether catering to different industries or projects with unique requirements, OEM Dutch wire mesh ensures that clients receive a product that fits seamlessly into their operations.

oem dutch wire mesh

2. Superior Filtration The unique structure of Dutch wire mesh allows for excellent filtration capabilities. The coarse outer layer captures larger particles, while the finer inner layer filters out smaller particulates. This dual-layer system enhances the overall efficiency of filtration processes, making it essential in applications like fluid filtration, air filtration, and soundproofing.

3. High Strength and Durability Dutch wire mesh is renowned for its strength and durability. The sturdy construction, paired with high-grade materials, ensures that the mesh can withstand harsh conditions and heavy use. This resilience translates into fewer replacements and lower operational costs over time, a critical consideration for businesses aiming to improve their bottom lines.

4. Easy Handling and Installation OEM Dutch wire mesh is designed for user-friendliness. It can be easily molded, cut, and shaped to fit various applications without compromising its structural integrity. This feature simplifies the installation process, reducing labor time and costs, which is especially beneficial for projects with tight deadlines.

5. Versatility Across Industries The applications of OEM Dutch wire mesh are vast and varied. Its effectiveness in filtration makes it a favored choice in industries such as pharmaceuticals, food and beverage, petrochemicals, and mining. Additionally, it is used in architectural applications for aesthetic and functional purposes, showcasing its versatility.

Conclusion

In summary, OEM Dutch wire mesh is an exceptional product that meets the diverse needs of modern industries. With its customizable features, superior filtration capabilities, and impressive durability, it stands out as a reliable solution. As industries continue to evolve and seek innovative materials to enhance their operations, Dutch wire mesh will undoubtedly remain at the forefront of filtration technology. By investing in this solution, businesses can expect improved operational efficiency, reduced costs, and ultimately, a competitive edge in their respective markets. Whether you're involved in manufacturing, construction, or any industry that requires effective filtration and separation, OEM Dutch wire mesh is the answer to your needs.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025