Aug . 13, 2024 09:32 Back to list

Discover Affordable High-Quality Fine Mesh Screening Options for Your Needs Today

Understanding the Importance of Fine Mesh Screening in Various Applications

Fine mesh screening is a crucial process in a wide range of industries, from agriculture and food processing to pharmaceuticals and manufacturing. The phrase “buy fine mesh screening” highlights the growing demand for high-quality screening products that can efficiently separate particles of different sizes, ensuring purity, quality, and optimal performance in various applications.

What is Fine Mesh Screening?

Fine mesh screening involves the use of specialized screens made from materials such as stainless steel, nylon, or polyester, designed with a mesh size that can filter out small particles while allowing desired materials to pass through. The mesh size can vary, typically ranging from 10 microns to several millimeters, depending on the specific requirements of the application. Fine mesh screens are used to separate materials, remove contaminants, and improve product quality.

Applications of Fine Mesh Screening

1. Food and Beverage Industry In the food processing sector, fine mesh screens are employed to remove impurities, such as seeds, fibers, and dust, from products like flour, sugar, and grains. They ensure that food items meet safety standards and improve the overall quality of the final product. In beverage production, screens help in clarifying liquids by filtering out solids from juices, wines, and beers.

2. Pharmaceuticals The pharmaceutical industry relies heavily on fine mesh screening to ensure that active ingredients are properly measured and contaminants are eliminated. Precise particle size distribution is essential in drug formulation, and fine screens help achieve this, contributing to the efficacy and safety of pharmaceutical products.

3. Mining and Mineral Processing Fine mesh screens are critical in the mining industry for separating valuable minerals from unwanted materials. The ability to sift through large quantities of material and isolate fine particles allows for more efficient recovery of precious metals and minerals, reducing waste and increasing profitability.

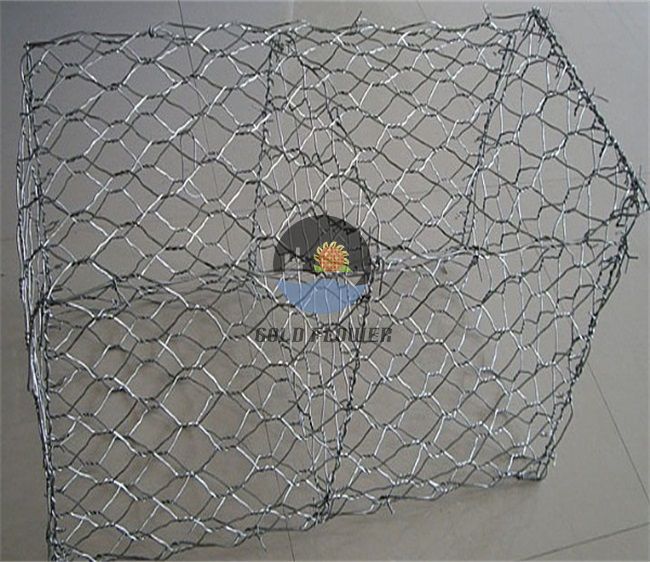

buy fine mesh screening

4. Chemical and Petrochemical Industries In these industries, fine mesh screening is used to refine raw materials and ensure product consistency. It helps filter out particulates, ensuring that chemical processes run smoothly and that the final products meet regulatory standards.

5. Environmental Applications Fine mesh screening plays a significant role in environmental protection efforts, such as wastewater treatment and air filtration. Screens effectively remove particulate matter from wastewater, ensuring that harmful substances are not discharged into the environment. In air filtration, fine mesh screens capture dust and airborne contaminants, promoting healthier living conditions.

Choosing the Right Fine Mesh Screen

When considering purchasing fine mesh screening products, it’s essential to assess several factors, including mesh material, size, and configuration. Stainless steel screens are durable and resistant to corrosion but may be more expensive than nylon or polyester options. It is also vital to determine the specific mesh size required for your application, as this directly impacts the efficiency of the screening process.

Furthermore, working with reputable suppliers is crucial to ensure the quality and reliability of the fine mesh screening products. High-quality screens can significantly enhance operational efficiency, reduce downtime, and contribute to the overall success of a business.

Conclusion

In conclusion, the importance of fine mesh screening transcends various industries, underscoring its key role in ensuring product quality, safety, and efficiency. As businesses strive to meet higher standards and regulatory requirements, investing in reliable fine mesh screening solutions is not just an option but a necessity. Whether you’re in food processing, pharmaceuticals, mining, or environmental protection, understanding how to choose and implement fine mesh screening will undoubtedly lead to better outcomes and increased success in your operations.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025