Aug . 12, 2024 11:02 Back to list

Durable and Efficient Woven Wire Mesh Sieves for High-Performance Filtration and Separation Needs

The Importance of High-Quality Woven Wire Mesh Sieves

Woven wire mesh sieves have become essential tools in various industries, including food processing, pharmaceuticals, mining, and laboratory research. These sieves are crafted from high-quality materials that ensure durability, precision, and efficiency in particle separation processes. In this article, we will explore the significance of high-quality woven wire mesh sieves, their applications, and the advantages they offer.

Understanding Woven Wire Mesh Sieves

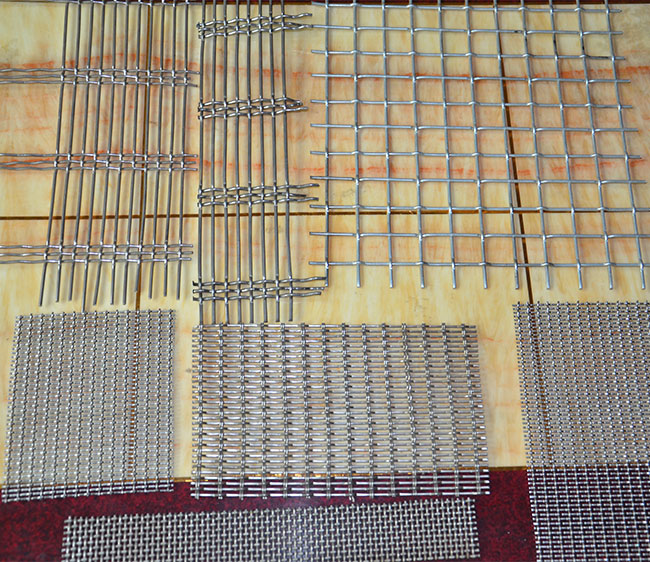

Woven wire mesh sieves consist of interwoven strands of wire, creating a grid-like structure that allows for the separation of different particle sizes. The quality of the woven wire mesh is paramount, as it directly affects the performance and longevity of the sieve. High-quality sieves feature tightly woven strands that minimize the risk of deformation and ensure consistent openings for filtration.

Applications in Various Industries

1. Food Processing In the food industry, high-quality mesh sieves are crucial for processes like separating flour from bran or sifting spices. They ensure that food products are free from contaminants and meet safety standards.

2. Pharmaceuticals The pharmaceutical industry relies on precise measurements and contaminant-free materials. High-quality woven wire mesh sieves are employed to separate active pharmaceutical ingredients (APIs) and ensure proper granulation.

3. Mining and Mineral Processing In mining, sieves are used to separate valuable minerals from ore. High-quality woven wire mesh ensures that particles are efficiently sorted based on size, which is critical for maximizing resource extraction.

4. Laboratory Research Researchers often utilize woven wire mesh sieves for sample preparation and analysis. The reliable performance of high-quality sieves ensures that experimental results are accurate and reproducible.

high quality woven wire mesh sieves

Advantages of High-Quality Sieves

Investing in high-quality woven wire mesh sieves comes with several advantages

1. Durability Woven wire mesh made from high-grade materials exhibits greater resistance to wear and tear. This durability translates to a longer lifespan for the sieves, reducing the need for frequent replacements and thereby saving costs in the long run.

2. Precision The precision engineering involved in creating high-quality sieves ensures that the mesh openings are uniform and consistent. This is crucial for achieving accurate particle size separation, which is vital in industries where precision is paramount.

3. Ease of Cleaning High-quality woven wire mesh sieves are designed for easy cleaning. Their smooth surfaces and sturdy construction mean that they can be effectively cleaned and maintained without damaging the mesh, ensuring compliance with hygiene standards.

4. Customizability Many manufacturers offer custom solutions for woven wire mesh sieves, providing clients with tailored mesh sizes and materials based on specific industry requirements. This customization enhances the sieve’s effectiveness in various applications.

Conclusion

High-quality woven wire mesh sieves play a crucial role in ensuring efficiency and safety across multiple industries. Their durability, precision, ease of cleaning, and customizability make them an invaluable asset in applications ranging from food processing to pharmaceuticals and beyond. As industries continue to evolve and demand higher standards, the importance of investing in high-quality sieves cannot be overstated. By choosing high-quality woven wire mesh sieves, businesses can ensure optimal performance and reliability in their operations, leading to improved productivity and quality control.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025