Aug . 13, 2024 21:09 Back to list

Durable and Elegant High-Quality Knitted Metal Mesh for Versatile Applications and Unique Designs

The Versatility and Benefits of High-Quality Knitted Metal Mesh

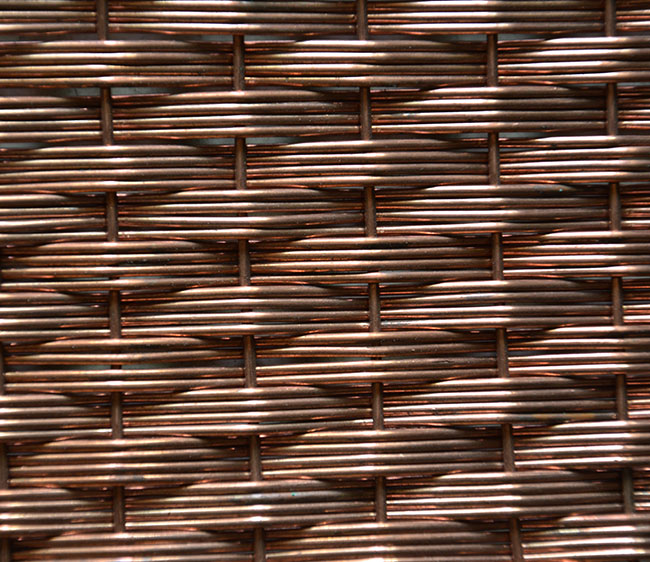

Knitted metal mesh has emerged as a prominent material in various industries due to its unique properties and aesthetic appeal. Unlike traditional metal mesh fabrics, which are typically woven, knitted metal mesh is created through a process that interlocks metal wires in a series of continuous loops. This innovative manufacturing technique contributes to the versatility, strength, and functionality of the material, making it an ideal choice for a wide array of applications.

The Versatility and Benefits of High-Quality Knitted Metal Mesh

In architectural design and construction, high-quality knitted metal mesh serves both functional and artistic purposes. It is frequently used in facades, canopies, and interior partitions, providing not only structural support but also a visually captivating element. The mesh can be finished in various colors and textures, which allows designers to create unique visual effects, play with light, and generate a sense of depth. Furthermore, the use of metal mesh can contribute to the overall sustainability of a building, as it is often made from recyclable materials and can help regulate temperature through its natural ventilation properties.

high quality knitted metal mesh

In the industrial sector, knitted metal mesh is utilized for filtration and separation processes. The unique geometry of this woven material exhibits a combination of high flow rates and efficient filtration capabilities. It is commonly found in applications such as oil and gas filtration systems, water treatment plants, and chemical processing, where reliability and durability are paramount. The resilience of knitted metal mesh against corrosion and wear makes it suitable for these demanding environments, ensuring a long operational life and reduced maintenance costs.

Another critical advantage of high-quality knitted metal mesh is its ability to resist deformation under stress. With its inherent elasticity, knitted metal mesh can withstand significant mechanical forces without losing its shape or function. This characteristic is particularly important in industries where safety and reliability take precedence. For example, in automotive manufacturing, knitted metal mesh can be used in components that require both strength and flexibility, ensuring the performance of vehicles under various driving conditions.

Moreover, knitted metal mesh enhances safety in multiple applications. The material can be used in protective clothing, where it acts as a lightweight barrier against cuts and abrasions, making it ideal for industries such as construction and manufacturing. Its fire-resistant properties further contribute to workplace safety, providing an added layer of protection for employees in high-risk environments.

In conclusion, high-quality knitted metal mesh showcases an impressive blend of versatility, strength, and aesthetics across a wide range of applications. Its flexibility makes it suitable for architectural designs, while its efficiency in filtration processes ensures reliability in industrial settings. As industries continue to prioritize sustainability and safety, the demand for knitted metal mesh will likely proliferate. With continuous advancements in manufacturing techniques and the exploration of new uses, knitted metal mesh stands at the forefront of innovative materials, poised to meet the diverse needs of the modern world.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025