Aug . 11, 2024 14:14 Back to list

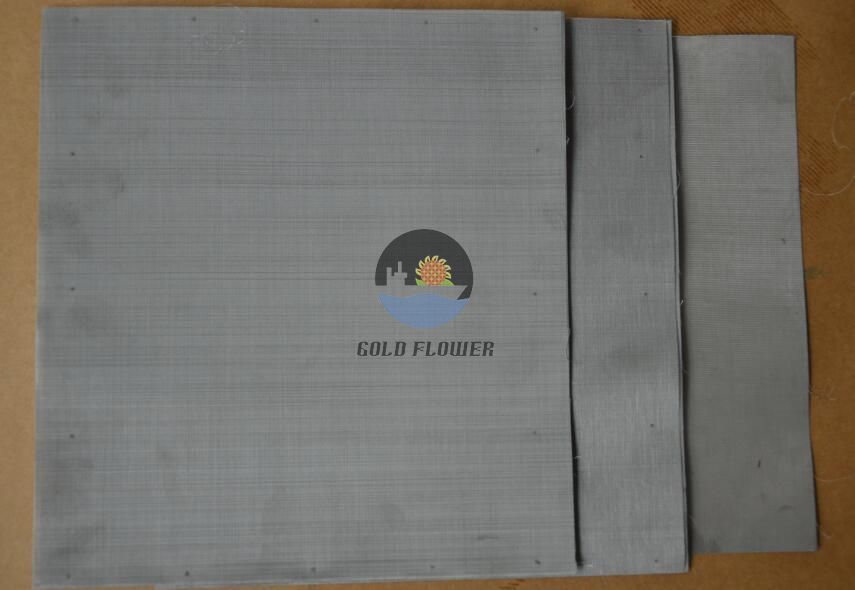

Durable High-Performance Steel Wire Screens for Enhanced Industrial Applications and Filtration Solutions

High-Quality Steel Screen Wire An Essential Component in Various Industries

In today's industrial landscape, high-quality steel screen wire plays a pivotal role in a multitude of applications. From construction and mining to agriculture and waste management, the demand for durable and reliable screening solutions has led to significant advancements in wire manufacturing technologies. This article explores the characteristics, applications, and advantages of high-quality steel screen wire.

Characteristics of High-Quality Steel Screen Wire

High-quality steel screen wire is primarily characterized by its strength, durability, and resistance to wear and corrosion. Typically made from high-carbon steel, this type of wire exhibits exceptional tensile strength—making it suitable for heavy-duty applications. Furthermore, advanced manufacturing processes such as cold drawing and wire coating enhance its properties, leading to improved performance in various environments.

The wire is available in various gauges and mesh sizes, which provide flexibility for different screening requirements. Whether for sifting fine particles or sorting larger materials, the versatility of steel screen wire ensures it meets the specifications of numerous industries.

Applications Across Industries

1. Mining and Quarrying In the mining and quarrying sectors, high-quality steel screen wire is indispensable for separating material based on size. Screens made from this wire facilitate the efficient sorting of minerals, ores, and aggregates, ensuring that only the right-sized materials move forward in processing. They can withstand the harsh conditions of mining operations, including exposure to abrasive materials and extreme temperatures.

2. Construction The construction industry frequently utilizes steel screen wire for reinforcement in concrete, as well as for creating sifting screens in aggregate processing. High-quality wire mesh ensures structural integrity while also allowing for effective drainage and ventilation in constructions.

high quality steel screen wire

3. Agriculture In agriculture, steel screen wire serves various functions, such as in soil sifting and in the production of animal enclosures. The strong resistance to rust and corrosion makes it ideal for outdoor use, ensuring longevity and reliability in agricultural operations.

4. Waste Management Steel screen wire is also useful in waste management facilities, where it is used to sort recyclable materials. Its strength allows it to handle heavy loads without bending or breaking, making it ideal for sorting various types of waste materials effectively.

Advantages of High-Quality Steel Screen Wire

The benefits of using high-quality steel screen wire are manifold. First and foremost, its durability means reduced maintenance and replacement costs over time. Businesses can avoid the downtime associated with frequent equipment failures, thereby increasing overall productivity.

Moreover, high-quality steel screen wire demonstrates excellent resistance to corrosion, especially when coated with protective layers such as galvanization. This resistance extends the lifespan of the wire, making it a wise investment for any industry reliant on screening operations.

Another advantage is the cost-effectiveness. While the initial investment may be higher than lower-quality alternatives, the longevity and durability of high-quality steel screen wire translate into cost savings in the long run. Businesses can allocate resources more efficiently, knowing that their screening solutions will perform reliably over time.

Conclusion

In conclusion, high-quality steel screen wire is a critical component in various sectors, providing essential solutions for material separation and processing. Its strength, versatility, and durability set it apart from lower-quality alternatives, making it a preferred choice for industries that value performance and reliability. As technology continues to advance, we can expect further innovations in steel wire production, enhancing its applications and effectiveness across the board.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025