Jul . 31, 2024 20:23 Back to list

Durable High-Quality SS 316L Wire Mesh for Various Industrial Applications and Projects

High-Quality SS 316L Wire Mesh A Comprehensive Overview

In the world of industrial applications, materials play a crucial role in the performance, durability, and efficiency of products. Among these materials, stainless steel wire mesh, especially of grade SS 316L, has garnered significant attention due to its exceptional properties and versatility. This article delves into the characteristics, advantages, applications, and maintenance of high-quality SS 316L wire mesh.

Understanding SS 316L Wire Mesh

Stainless steel 316L is an austenitic alloy known for its excellent corrosion resistance, particularly in chloride environments. The “L” in 316L stands for low carbon, which means it has a lower amount of carbon compared to standard 316 stainless steel. This composition provides enhanced resistance to intergranular corrosion, making it ideal for use in high-temperature applications and environments with high salinity.

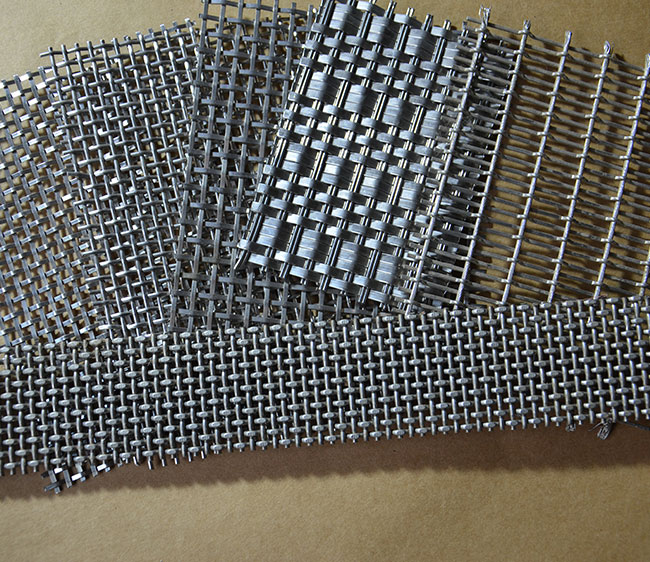

SS 316L wire mesh is produced by weaving stainless steel wires together to create a grid-like structure. The mesh can be manufactured in various sizes, openings, and wire diameters, tailoring it to specific applications and requirements. Its smooth surface and uniform openings make it an excellent choice for filtration and separation processes.

Advantages of SS 316L Wire Mesh

1. Corrosion Resistance One of the most prominent features of SS 316L wire mesh is its remarkable resistance to rust and corrosion. This makes it a preferred choice in industries where exposure to harsh chemicals, salty waters, or extreme weather conditions is common.

2. Durability SS 316L wire mesh is exceptionally strong and durable, able to withstand mechanical stress and extreme temperatures. This resilience extends the lifespan of products and infrastructures, reducing the frequency of repairs and replacements.

3. Low Maintenance Unlike other types of mesh made from carbon steel or lower-grade stainless steels, SS 316L requires minimal maintenance. It does not chip, peel, or fade, which contributes to long-term cost savings.

4. Versatility This type of wire mesh can be used in a variety of applications, including filtration, separation, security fencing, and architectural elements. Its adaptability makes it essential across industries such as food and beverage, pharmaceuticals, petrochemicals, and construction.

high quality ss 316l wire mesh

5. Aesthetic Appeal The polished finish of SS 316L wire mesh provides not only functional benefits but also enhances aesthetic appeal. It is often used in architecture and design to create visually pleasing barriers and partitions.

Applications of SS 316L Wire Mesh

1. Filtration and Separation SS 316L wire mesh is extensively utilized in filtration systems. It is ideal for filtering liquids and gases due to its uniform openings and resistance to clogging.

2. Marine Industry Given its corrosion resistance, SS 316L is widely used in the marine industry for boat fittings, seawater applications, and various components exposed to harsh marine conditions.

3. Food Processing and Medical Applications The mesh’s low carbon content and resistance to bacteria make it suitable for food processing and pharmaceutical applications, where hygiene and cleanliness are paramount.

4. Construction SS 316L wire mesh is employed in construction for reinforcing concrete structures, creating safety barriers, and as architectural features in modern designs.

Maintenance and Care

To maintain the quality of SS 316L wire mesh, regular cleaning is essential, particularly in environments where it is exposed to corrosive elements. A mild detergent and soft brush are usually sufficient to keep the mesh looking new. It is advisable to avoid abrasive materials that could damage the surface.

Conclusion

High-quality SS 316L wire mesh stands out as a vital material in various industries. With its unrivaled characteristics, including corrosion resistance, durability, and aesthetic versatility, it is an excellent investment for companies seeking reliable and long-lasting solutions. Whether in filtration, construction, or marine applications, SS 316L wire mesh continues to set the standard for quality and performance.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025