Aug . 14, 2024 03:44 Back to list

Exploring Options for Purchasing OEM Wire Mesh for Various Applications and Industries

The Importance of OEM Buying for Wire Mesh A Comprehensive Overview

In today's fast-paced manufacturing and industrial landscape, the demand for high-quality wire mesh products has surged dramatically. From construction to filtration, agriculture to security, wire mesh plays an essential role in numerous applications. As industries seek to optimize their operations and reduce costs, Original Equipment Manufacturer (OEM) buying has emerged as a crucial strategy for sourcing wire mesh. This article delves into the significance of OEM buying for wire mesh, outlining its benefits, challenges, and best practices.

Understanding OEM Buying

OEM buying involves procuring products from manufacturers who produce components or assemblies that can be integrated into a company's end products. In the context of wire mesh, OEM buyers often seek customized solutions that meet specific engineering requirements. By collaborating directly with wire mesh manufacturers, companies can ensure that they receive products that are tailored to their precise needs.

Benefits of OEM Buying for Wire Mesh

1. Customization and Flexibility One of the primary advantages of OEM buying is the ability to obtain customized wire mesh products. Manufacturers can design wire mesh to varying specifications, including different materials, wire diameters, and mesh openings. This flexibility enables businesses to find solutions that perfectly align with their operational requirements.

2. Improved Quality Control Partnering with OEM manufacturers allows businesses to maintain high standards of quality. Most OEMs have stringent quality assurance protocols in place, ensuring that the wire mesh produced meets industry standards. This commitment to quality is essential in applications where safety and reliability are paramount.

3. Cost Efficiency OEM buying can lead to significant cost savings for companies. By eliminating middlemen and sourcing directly from manufacturers, businesses can often secure lower prices. Additionally, OEM relationships can result in bulk purchasing discounts and favorable payment terms, further enhancing cost efficiency.

4. Access to Expertise Engaging with OEM manufacturers provides buyers with access to specialized knowledge and expertise. Manufacturers often have in-depth knowledge of materials, production processes, and market trends, which can be invaluable in helping companies make informed purchasing decisions.

Challenges in OEM Buying

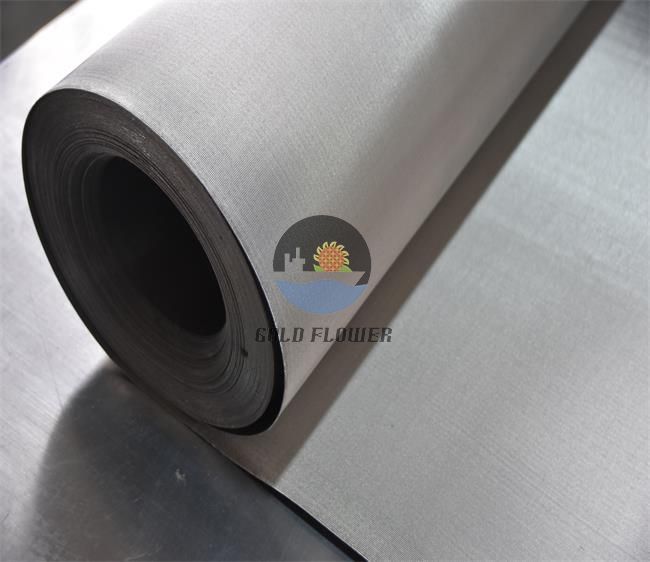

oem buying wire mesh

While the benefits of OEM buying are substantial, there are also challenges that companies may face. One significant obstacle is the potential for communication barriers, especially when dealing with international suppliers. Misunderstandings regarding specifications or quality standards can lead to costly mistakes.

Additionally, the reliance on a single supplier for wire mesh may create risks. If an OEM manufacturer encounters production delays or issues, it can disrupt the supply chain. Therefore, it's essential for companies to establish robust contingency plans.

Best Practices for OEM Buying

To optimize the OEM buying process for wire mesh, companies should consider the following best practices

1. Conduct Thorough Research Before engaging an OEM partner, conduct comprehensive research on potential suppliers. Assess their reputation, production capabilities, and experience within the industry.

2. Establish Clear Specifications Clearly define product specifications, quality standards, and delivery timelines to minimize the risk of misunderstandings.

3. Build Strong Relationships Foster open communication and collaboration with OEM partners. A strong working relationship can facilitate problem-solving and ensure a smooth supply chain.

4. Evaluate Multiple Suppliers While developing an OEM partnership can be beneficial, it's wise to evaluate multiple suppliers to mitigate risks and maintain competitive pricing.

Conclusion

OEM buying for wire mesh presents a valuable opportunity for companies seeking customized, high-quality solutions that enhance operational efficiency. By leveraging the advantages of OEM partnerships, businesses can not only reduce costs but also ensure that they obtain wire mesh products tailored to their specific needs. With careful consideration and strategic planning, companies can navigate the challenges of OEM buying and reap the rewards in their respective industries.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025