Jul . 31, 2024 09:57 Back to list

Exploring the Benefits and Applications of Alloy Mesh in Various Industries and Technologies

Understanding Alloy Mesh Applications, Benefits, and Manufacturing

Alloy mesh is a versatile and essential material used in various industries due to its unique properties. Composed of metallic alloys, these meshes provide excellent strength, durability, and resistance to corrosion, making them suitable for a wide range of applications. This article explores the composition, applications, benefits, and manufacturing processes of alloy mesh.

Composition and Types of Alloy Mesh

Alloy meshes are typically made from a combination of metals, such as stainless steel, aluminum, brass, and other alloys. The specific composition of the alloy determines the mesh's properties, including its strength, weight, and resistance to environmental factors. For example, stainless steel mesh is renowned for its high tensile strength and corrosion resistance, making it ideal for harsh environments like chemical processing and marine applications. On the other hand, aluminum alloy mesh is lightweight and resistant to oxidation, making it suitable for applications requiring lower weight without compromising strength.

Applications of Alloy Mesh

The applications of alloy mesh are extensive and diverse. In the industrial sector, it is used in filtration systems, where the mesh acts as a barrier to separate solids from liquids or gases. This is particularly important in industries such as wastewater treatment, food and beverage processing, and petrochemical refining.

In the construction industry, alloy mesh is utilized for reinforcement in concrete structures, providing additional tensile strength and durability. It is commonly used in bridges, buildings, and other infrastructure projects to enhance the overall structural integrity.

In electronics, alloy mesh serves as a key component in EMI shielding, where it protects sensitive electronic devices from electromagnetic interference

. The mesh allows for the safe operation of devices while ensuring optimal performance without distractions from external signals.Benefits of Alloy Mesh

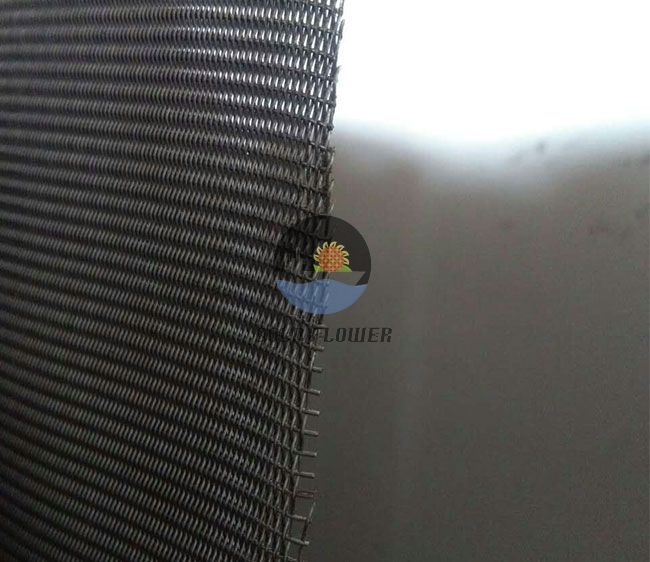

alloy mesh

The primary benefits of alloy mesh stem from its unique properties. Firstly, the strength-to-weight ratio of alloy mesh is superior to many other materials, allowing for applications that require robust structures without adding excessive weight. This feature is particularly valuable in aerospace and automotive industries, where weight savings can lead to improved fuel efficiency and performance.

Corrosion resistance is another significant advantage. Alloy meshes, particularly those made from stainless steel, can withstand harsh chemical environments and exposure to moisture without deteriorating. This longevity leads to reduced maintenance costs and longer lifespans for equipment, making alloy mesh a cost-effective choice in the long run.

Moreover, alloy mesh offers versatility in terms of design and functionality. It can be customized in terms of mesh size, thickness, and weave pattern to suit specific needs. This flexibility allows engineers and designers to create solutions that precisely match their requirements.

Manufacturing Processes

The manufacturing of alloy mesh involves several stages, including material selection, weaving or welding, and finishing. The process begins with selecting the appropriate alloy based on the desired properties. Next, the alloys are either woven into a mesh pattern or welded to form a sturdy structure. Advanced technologies like laser cutting and automated weaving machines are increasingly used to enhance precision and efficiency in production.

Finally, finishing processes such as electroplating or coating may be applied to improve corrosion resistance or aesthetic appeal. These finishes can range from simple powder coating to more complex chemical treatments designed to enhance the performance of the mesh.

Conclusion

Alloy mesh is an indispensable material in modern industry, offering a formidable combination of strength, durability, and versatility. As technology advances and industries evolve, the demand for high-quality alloy mesh will continue to grow, paving the way for innovative applications and solutions across various sectors. Whether in construction, filtration, or electronics, alloy mesh remains a crucial element in enhancing performance and ensuring safety.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025