Aug . 14, 2024 14:45 Back to list

Exploring the Properties and Applications of Mesh SS316 in Various Industries and Environments

The Versatility of Mesh SS316 A Comprehensive Overview

Mesh SS316, or Stainless Steel 316 mesh, is a highly sought-after material in various industries due to its exceptional properties and versatility. The SS stands for stainless steel, and the 316 designation refers to a specific grade known for its superior resistance to corrosion and high temperatures. This article aims to explore the characteristics, applications, and benefits of Mesh SS316, highlighting why it has become an indispensable material in modern engineering and manufacturing.

Characteristics of Mesh SS316

One of the defining features of SS316 is its composition, which typically includes iron, chromium, nickel, and molybdenum. The inclusion of molybdenum enhances its resistance to pitting and crevice corrosion, particularly in chloride environments, making it particularly valuable in marine applications and chemical processing.

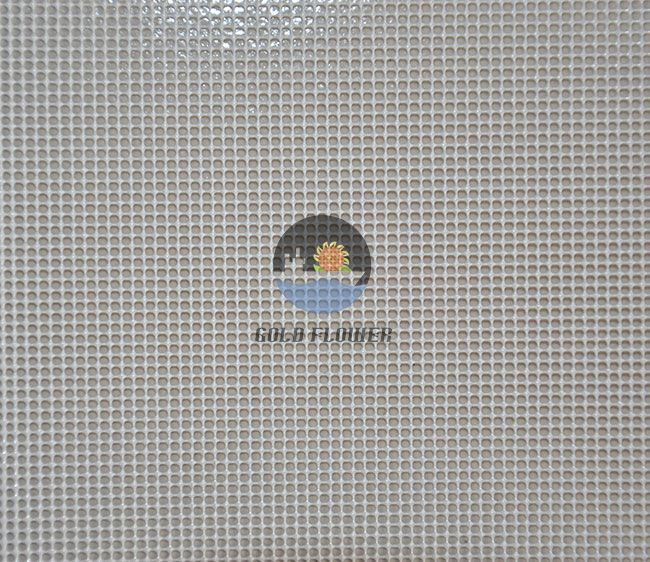

The mesh structure itself can vary in terms of weave patterns and opening sizes, affecting its mechanical properties and suitability for different applications. Common weaving techniques include plain weave, twill weave, and Dutch weave, which cater to varying needs for filtration, reinforcement, and strength. Mesh SS316 also boasts high tensile strength, enabling it to withstand significant mechanical stress while maintaining its shape and integrity.

Applications of Mesh SS316

The versatility of Mesh SS316 leads to its use in a wide array of applications across different sectors.

1. Chemical Processing In industries dealing with corrosive substances, SS316 mesh is employed for filtration, separation, and containment. It ensures that harmful chemicals do not compromise equipment integrity or product quality.

2. Marine Environments The resistance to saltwater corrosion makes Mesh SS316 an ideal choice for marine applications, including boat building, fishing nets, and underwater structures.

3. Food and Beverage Industry SS316 is often used in food processing and production due to its non-reactive nature and ease of cleaning. Mesh screens and filters made from this material help in maintaining hygiene standards while ensuring product integrity.

mesh ss316

4. Oil and Gas In the extraction and processing of oil and gas, Mesh SS316 is used in filtration systems to remove impurities without degrading in harsh environments.

5. Architectural Applications SS316 mesh has gained popularity in architectural design, serving as decorative panels, railing infills, and sunshades. Its aesthetic appeal combined with durability makes it a favorite for modern buildings.

Advantages of Using Mesh SS316

1. Corrosion Resistance The primary advantage of SS316 is its exceptional resistance to corrosion. This property extends the lifespan of products made from it, reducing maintenance costs and downtime.

2. High-Temperature Resistance SS316 can withstand elevated temperatures, making it suitable for high-heat applications without losing strength or structural integrity.

3. Durability Due to its robust nature, Mesh SS316 can endure mechanical stress, vibration, and other physical challenges. This durability makes it suitable for demanding environments.

4. Hygienic Properties The non-porous surface of stainless steel makes it easy to clean and reduces the buildup of bacteria, which is essential in food processing and medical applications.

5. Recyclability As a sustainable material, SS316 can be recycled without loss of quality, making it an environmentally friendly choice for manufacturers.

Conclusion

In summary, Mesh SS316 stands out as a versatile and reliable material across multiple industries. Its unique properties—such as corrosion and temperature resistance, durability, and hygienic characteristics—make it an ideal choice for applications ranging from food and beverage processing to marine engineering. As industries continue to evolve and demand higher standards, the role of Mesh SS316 is expected to grow, reinforcing its place as a cornerstone of modern manufacturing and engineering solutions.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025