Nov . 11, 2024 05:53 Back to list

Versatile Applications of Wire and Wire Mesh in Various Industries

The Intricacies of Famous Wire and Wire Mesh A Closer Look

Wire and wire mesh have become essential materials in various industries, reflecting a blend of strength, versatility, and functionality. The significance of these materials can be traced back to their diverse applications, adaptability, and the technological advancements that have enhanced their manufacturing processes. This article delves into the fascinating world of wire and wire mesh, highlighting their historical evolution, types, and applications, and shedding light on why they have garnered fame across different sectors.

Historical Overview

The use of wire dates back thousands of years, with evidence suggesting that primitive societies began working with metal wires for decorative and functional purposes. Early forms of wire were handmade, often drawn through primitive dies to achieve thinner gauges. The industrial revolution, however, revolutionized wire production by introducing new machinery that allowed for mass manufacturing. As a result, various forms of wire were produced, catering to the growing demands of agriculture, construction, and manufacturing.

Wire mesh emerged as a natural progression of wire technology. The foundational concept involves weaving or welding wires together to form a grid-like structure. This advancement has made wire mesh an indispensable element in numerous applications, from construction sites to household uses.

Types of Wire and Wire Mesh

The types of wire and wire mesh are incredibly diverse, with each type serving specific functions

. Here are some of the most notable ones1. Welded Wire Mesh Also known as welded wire fabric, this type is created by welding wires at intersections. It is renowned for its strength and stability, making it ideal for construction projects, animal enclosures, and agricultural fencing.

2. Chain Link Fencing This form of wire mesh is a popular choice for security and fencing applications. Made from high-carbon steel wire, it offers durability and flexibility, making it suitable for residential and commercial properties.

famous wire and wire mesh

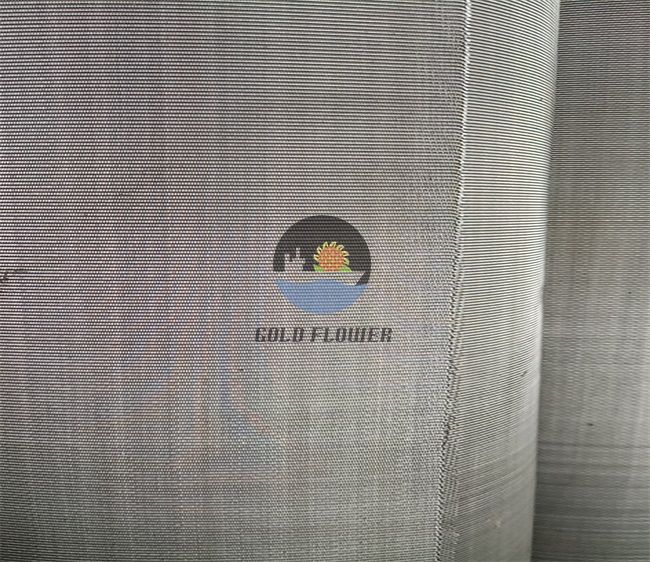

3. Stainless Steel Wire Mesh Esteemed for its resistance to corrosion and rust, stainless steel wire mesh is often used in environments where exposure to harsh conditions is prevalent. Industries such as food processing, chemical manufacturing, and pharmaceuticals benefit from its durability and hygienic properties.

4. Woven Wire Mesh This type incorporates a weaving process that creates a more flexible, lightweight product. It’s commonly used in filters, screens, and in architectural applications where aesthetics and functionality coalesce.

5. Expanded Metal Mesh Created by cutting and stretching a solid sheet of metal to form a mesh, expanded metal offers excellent strength and is often used in flooring, walkways, and security applications.

Applications of Wire and Wire Mesh

The versatility of wire and wire mesh enables their application in countless domains. In construction, welded wire mesh is used as a concrete reinforcement material, ensuring the structural integrity of buildings and bridges. In agriculture, wire fencing provides secure enclosures for livestock, effectively preventing escapes and protecting crops from wildlife.

In the realm of manufacturing, wire mesh screens are integral to processes such as sifting, screening, and separation. The food industry utilizes stainless steel wire mesh to create hygienic barriers in processing plants, ensuring safety and compliance with health regulations.

Additionally, the aesthetic appeal of woven wire mesh has made it a popular choice in architecture and interior design. From decorative partitions to unique facades, wire mesh is increasingly being embraced for its ability to blend functionality with striking visual appeal.

Conclusion

As industries continue to evolve, the importance of wire and wire mesh remains steadfast. Their strength, adaptability, and wide range of applications ensure that they will continue to be at the forefront of various sectors. With advances in technology further refining their production and capabilities, the future of wire and wire mesh holds endless possibilities. Whether it is in infrastructure, security, or creative architectural design, the fame of wire and wire mesh is well-deserved, symbolizing both innovation and utility in our modern world.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Fine & Durable

NewsAug.06,2025

-

CE Certified 250 Micron Stainless Steel Mesh Filter

NewsAug.04,2025

-

Premium Twill Weave Mesh for Industrial Filtration & Strength

NewsAug.03,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable Filter

NewsAug.02,2025

-

CE Certified 250 Micron Stainless Steel Filter Mesh | Premium

NewsJul.31,2025

-

CE Certified 250 Micron Stainless Steel Mesh | Premium Filter

NewsJul.31,2025