Dec . 01, 2024 14:47 Back to list

famous wire mesh 4 mm

The Versatility of Famous Wire Mesh A Focus on 4mm Specifications

Wire mesh has become an indispensable material in various industries, known for its strength, adaptability, and functionality. Among the different specifications available, 4mm wire mesh stands out for its unique properties and applications. This article explores the qualities of 4mm wire mesh, its manufacturing processes, and its diverse applications across various sectors.

Understanding 4mm Wire Mesh

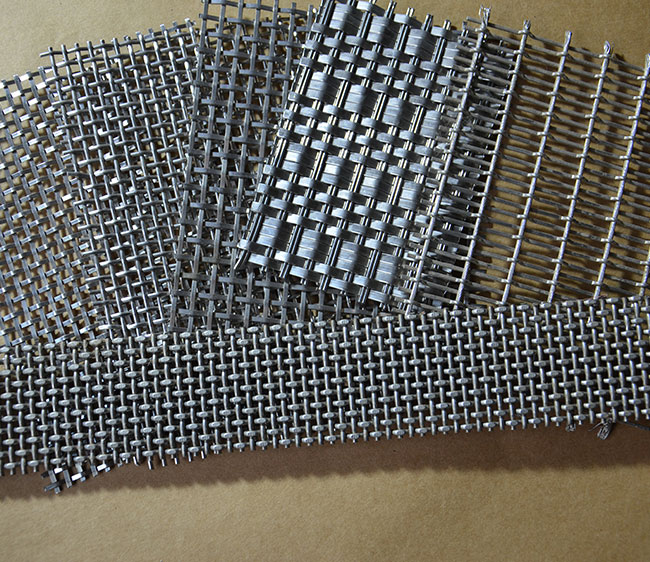

Wire mesh is a web-like structure made from thin, metal wires that are interwoven to create a grid. The term 4mm refers to the diameter of the wire used in its construction. This particular gauge strikes a balance between durability and flexibility, making it ideal for a range of applications. Typically, wire mesh is made from materials such as stainless steel, galvanized steel, or nylon, which enhance its durability and resistance to environmental conditions.

Manufacturing Process

The production of 4mm wire mesh involves several key steps. First, the wires are drawn to the desired thickness. The quality of the wire is crucial, as it determines the final product's strength and durability. Once the wires are produced, they are cut to specified lengths and woven or welded together to form the mesh. Two common fabrication methods include

1. Woven Wire Mesh Woven wire mesh is made by interlacing the wires at right angles to create a grid pattern. This method allows for flexibility and is commonly used in applications requiring easy customization, such as industrial and agricultural uses.

2. Welded Wire Mesh In contrast, welded wire mesh is produced by electrically welding the intersecting wires at their junctions. This results in a robust structure with enhanced load-bearing capacity, making it suitable for construction, fencing, and other heavy-duty applications.

Applications of 4mm Wire Mesh

famous wire mesh 4 mm

The versatility of 4mm wire mesh is reflected in its myriad applications across different sectors

1. Construction Industry In construction, 4mm wire mesh is often used for reinforcing concrete. Its strength helps prevent cracking and ensures the overall durability of buildings and structures. It is also employed in the creation of concrete slabs, walls, and floors.

2. Agriculture Farmers utilize 4mm wire mesh for fencing livestock, as it provides a sturdy barrier while allowing visibility and airflow. It is also used in creating supports for climbing plants and protecting crops from pests.

3. Industrial Uses In industrial settings, 4mm wire mesh serves several purposes, including safety screens, filtration systems, and material separation. Its ability to withstand abrasion and corrosion makes it invaluable in manufacturing environments.

4. Architecture and Design The aesthetic appeal of wire mesh is increasingly being recognized in architecture and interior design. 4mm wire mesh can be used in decorative railings, room dividers, and art installations, providing an industrial chic look while serving functional purposes.

5. Food Processing Stainless steel 4mm wire mesh is often utilized in the food industry for safety screens and to prevent contamination. Its non-corrosive properties make it ideal for environments that require regular cleaning and sterilization.

Conclusion

In conclusion, 4mm wire mesh is a prominent figure in the world of materials, thanks to its exceptional versatility and performance. From construction to agriculture and industrial applications, it serves critical roles while offering reliability and strength. As industries evolve and innovate, the demand for specialized wire mesh will likely continue to grow, further solidifying its status as a fundamental element in many sectors. Whether for practical use or artistic expression, the famous wire mesh remains a staple, proving that its value is greater than the sum of its parts.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025