Jul . 28, 2024 23:12 Back to list

Hexagonal Wire Netting Machine for CE Certification and Enhanced Production Efficiency

CE Certification and the Hexagonal Wire Netting Machine

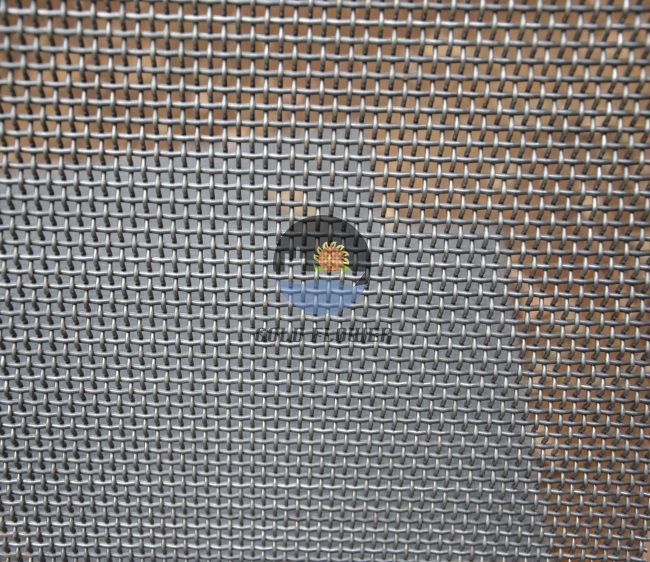

The hexagonal wire netting machine, a significant innovation in the wire processing industry, has revolutionized the way hexagonal wire mesh is produced. This mesh, made from high-quality steel or iron wire, is widely utilized in a variety of applications, including construction, agriculture, and landscaping. To ensure that these machines meet stringent safety and quality standards, CE certification plays a crucial role.

Understanding CE Certification

CE certification, a mandatory requirement in the European Economic Area (EEA), signifies that a product meets specific safety, health, and environmental protection standards. The CE marking on a product is a declaration by the manufacturer that their machine conforms to all relevant EU regulations. Obtaining CE certification assures customers that the hexagonal wire netting machine complies with essential safety directives, enhancing consumer trust and marketability.

Importance of Hexagonal Wire Netting Machines

Hexagonal wire netting machines are designed to produce hexagonal wire mesh efficiently and reliably. This type of mesh is essential for various applications - Agriculture It is commonly used for fencing poultry farms, enclosures for small animals, and erosion control. The mesh’s hexagonal shape allows for flexibility while providing strong containment. - Construction In building construction, hexagonal wire netting serves as reinforcement for concrete structures. It also acts as a protective barrier for scaffolding and temporary structures. - Landscaping Gardeners use hexagonal wire mesh for trellises, garden fencing, and decorative features.

Given the diverse applications, ensuring the reliable operation of the hexagonal wire netting machine is paramount. CE certification assures users of its reliability and safety.

Features of CE Certified Hexagonal Wire Netting Machines

CE certified hexagonal wire netting machines are equipped with advanced technology, ensuring high production efficiency and quality. Key features include

ce certification hexagonal wire netting machine

1. Safety Mechanisms These machines come with safety guards, emergency stop buttons, and other protective features to prevent accidents during operation. 2. Efficiency CE certified machines are designed for high-speed production, which enhances productivity while minimizing waste.

3. User-Friendly Interfaces Many models feature intuitive controls that make it easier for operators to adjust settings and monitor production.

4. Durability Constructed from robust materials, these machines are built to last, reducing the frequency of breakdowns and maintenance costs.

5. Versatility They can produce various mesh sizes and types, catering to different industrial needs.

The Process of CE Certification

The process of obtaining CE certification can be complex and usually involves several steps - Product Assessment Manufacturers must conduct a conformity assessment to ensure the machine meets all applicable EU directives. - Technical Documentation Detailed documentation is required, including design specifications, manufacturing processes, and results from safety testing. - Testing and Inspection Independent testing may be conducted by a notified body to verify compliance. - Declaration of Conformity Once compliance is confirmed, the manufacturer can issue a declaration of conformity and affix the CE marking.

Conclusion

In conclusion, CE certification is vital for hexagonal wire netting machines, ensuring they meet European safety and quality standards. By investing in CE certified machines, manufacturers not only enhance their product's credibility but also contribute to a safer working environment. The increasing demand for high-quality hexagonal wire mesh across various sectors further underscores the importance of these certified machines in today's industrial landscape.

share

-

Safety Mesh for Windows – Durable Mosquito and Insect Protection Solutions

NewsJul.08,2025

-

12x24x1 Air Filter – High Efficiency Replacement for Improved Air Quality

NewsJul.08,2025

-

Premium Stainless Steel Mosquito Mesh - Durable, Rust-Resistant Protection for Windows & Doors

NewsJul.08,2025

-

Premium Stainless Steel Garden Mesh for Lasting Durability Best & High Quality Mesh Solutions

NewsJul.07,2025

-

Gold and White Blackout Curtains – Elegant Light Blocking & Insulation for Home

NewsJul.07,2025

-

Premium Spa Filter Cartridge for Clean Water Spa Pool Filters Cartridges for Jacuzzi Durable, high-efficiency spa filter cartridge for spas and jacuzzis. Improve water quality—order your pool filter cartridge now!

NewsJul.07,2025