Aug . 13, 2024 08:36 Back to list

High-Quality Custom Wire Mesh Solutions for OEM Applications in Various Industries and Uses

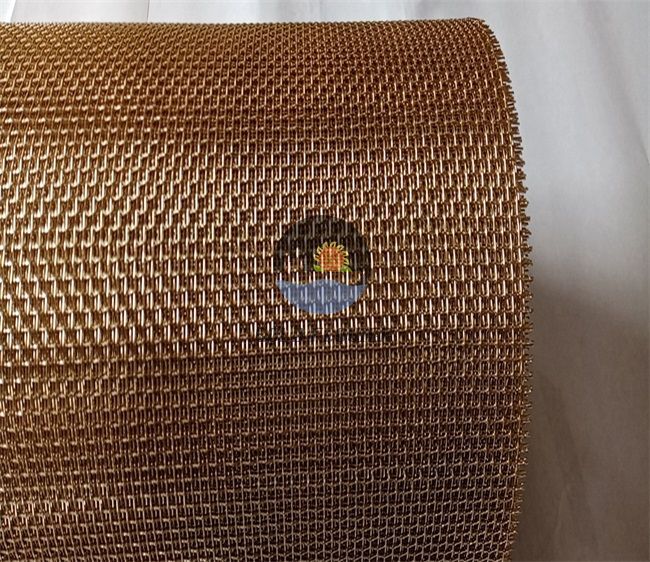

The Versatility of OEM Wire Mesh Metal

Wire mesh metal has become increasingly essential in various industries, thanks to its strength, durability, and versatility. Original Equipment Manufacturers (OEMs) utilize wire mesh for a multitude of applications, from construction and architecture to automotive and filtration. This article explores the attributes and applications of OEM wire mesh metal, illustrating its significance in modern manufacturing and design.

Understanding Wire Mesh Metal

Wire mesh metal is produced by weaving or welding metal wires together to create a grid-like pattern. The material can be made from various metals, including stainless steel, aluminum, and carbon steel. The choice of metal often depends on the intended application, with factors like corrosion resistance, strength, and weight playing crucial roles.

Key Advantages of OEM Wire Mesh Metal

1. Strength and Durability Wire mesh is exceptionally robust, capable of withstanding high levels of stress and pressure. This makes it ideal for construction applications, where structural integrity is paramount. Additionally, the durability of metal wire mesh ensures a long lifespan, reducing replacement costs and improving overall efficiency.

2. Versatility One of the standout features of wire mesh is its adaptability. OEMs can customize wire mesh to meet specific requirements, including varying mesh sizes, wire thicknesses, and material types. This ability to tailor the product makes wire mesh suitable for a wide array of applications across different industries.

3. Cost-Effectiveness The manufacturing process for wire mesh is relatively efficient, allowing for mass production without sacrificing quality. This results in a cost-effective material that can meet budgetary constraints while still fulfilling performance needs.

4. Air and Light Transparency Wire mesh is excellent for applications requiring ventilation, light, or visibility. This characteristic is particularly valuable in architectural designs, such as fencing, balustrades, and decorative panels, where aesthetics must be balanced with functionality.

5. Easy Installation and Maintenance Most wire mesh products are straightforward to install, often requiring only basic tools. Additionally, maintenance is generally minimal, involving simple cleaning procedures to prevent corrosion or blockage.

oem wire mesh metal

Applications of OEM Wire Mesh Metal

The applications of OEM wire mesh metal are vast and varied. Here are some notable areas where this versatile material is employed

- Construction In the construction industry, wire mesh is frequently used as reinforcement in concrete applications or as barriers for safety and security. It's also applied in the manufacture of grates and screens for building ventilation systems.

- Automotive Wire mesh is utilized for its durability and aesthetic appeal in various automotive applications, including grills, ventilation systems, and as components for filtering systems.

- Filtration One of the most significant applications of wire mesh is in filtration systems. From water treatment to air filtration, wire mesh can serve as a crucial element in separating solids from liquids or gases.

- Agriculture In agriculture, wire mesh is used in fencing, animal enclosures, and crop protection. Its strength and visibility make it an effective tool for safeguarding livestock and crops.

- Industrial Many industrial applications rely on wire mesh for sorting and sieving materials. It's commonly used in manufacturing processes, as well as in the production of various consumer products.

Conclusion

The versatility and reliability of OEM wire mesh metal make it an invaluable resource across multiple sectors. Its unique properties allow for a multitude of applications, from construction to automotive engineering. As industries continue to evolve, the demand for versatile materials like wire mesh will undoubtedly increase, driving innovation and the development of new applications. It is clear that wire mesh is more than just a simple material; it is a foundational component driving progress in modern manufacturing and design.

share

-

CE Certified Woven Wire Mesh Filters | Premium Filtration Solutions

NewsAug.19,2025

-

High-Performance Particle Filters: Optimal Mediums & Applications

NewsAug.18,2025

-

Competitive Screen Mesh Price | 1/4", 1/8", 1/2" Wire Mesh Screens

NewsAug.17,2025

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025