Jul . 30, 2024 18:57 Back to list

High-Quality Stainless Steel Wire Mesh Solutions for Various Industrial Applications in China

The Importance of Stainless Steel SS Wire Mesh in Modern Applications

Stainless steel wire mesh, often referred to in the industry as SS wire mesh, has become an indispensable material across various sectors due to its unique properties and versatility. Originating from the desire for a corrosion-resistant alternative to traditional steel meshes, stainless steel wire mesh is celebrated for its strength, durability, and aesthetic appeal. In China, the production and application of stainless steel wire mesh have witnessed significant growth, establishing the country as a key player in the global market.

One of the primary benefits of stainless steel SS wire mesh is its resistance to rust and corrosion. This characteristic is especially vital in industries that require long-lasting materials exposed to harsh environments. For instance, construction and architectural sectors frequently rely on stainless steel mesh for safety and security applications, such as fencing and reinforcing concrete structures. The mesh can withstand weather-induced wear and tear better than many other materials, thus reducing maintenance costs and enhancing the lifespan of products made from it.

The Importance of Stainless Steel SS Wire Mesh in Modern Applications

The automotive and aerospace sectors also benefit from the use of stainless steel SS wire mesh. Here, the material is used in applications such as exhaust systems, heat shields, and other components that require exceptional heat resistance and low weight. The robust nature of stainless steel ensures that vehicles maintain their performance standards while minimizing the likelihood of component failure due to environmental stresses.

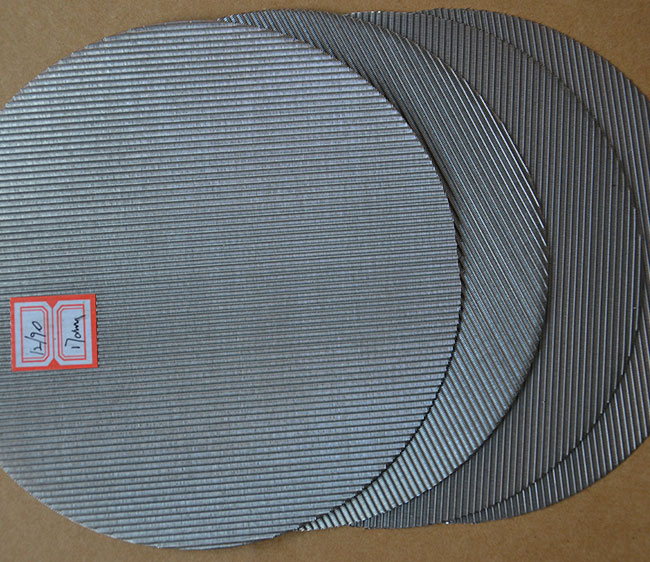

china stainless steel ss wire mesh

Moreover, the rise of sustainability awareness has propelled the demand for stainless steel wire mesh in environmental engineering applications. The material is 100% recyclable, which resonates with the growing emphasis on sustainable development and eco-friendly practices. In filtration systems aimed at water treatment, stainless steel SS wire mesh is favored for its longevity and effectiveness, ensuring that contaminated water can be purified efficiently over time.

China, with its extensive manufacturing capabilities, has become a central hub for the production of stainless steel SS wire mesh. The country boasts advanced technology and skilled labor, allowing for the mass production of high-quality wire mesh at competitive prices. This not only meets domestic demand but also supports exports to international markets, where the quality of Chinese stainless steel products is increasingly recognized.

As the stainless steel wire mesh market continues to evolve, innovation will play a critical role in enhancing its applications. Research into new alloy compositions and manufacturing techniques could lead to even more specialized products designed for niche markets. Additionally, as industries move toward automation, the integration of stainless steel wire mesh in robotics and automated systems could open up new opportunities for development.

In conclusion, stainless steel SS wire mesh is a vital material that has found applications in various industries due to its unique properties and versatility. As global markets evolve and the demand for sustainable and durable materials increases, the significance of stainless steel wire mesh, particularly from China, will only continue to grow. Emphasizing its benefits will ensure its place at the forefront of innovation and efficiency in industrial applications.

share

-

Premium Stainless Steel Netting Mesh Discount & ODM Stainless Steel Wire Mesh Solutions

NewsJun.24,2025

-

High-Quality Screen Stone for Modern Stone Screen Walls Elegant Facade Solutions

NewsJun.10,2025

-

High Quality Wire Filter – Cheap Stainless Steel Filter Wire Mesh Cloth & Wire Mesh Filter Solutions

NewsJun.10,2025

-

5 Micron Water Filter Cartridge - Premium Sediment Filtration, Universal Fit

NewsJun.10,2025

-

High Quality CE-Certified Gabion Boxes with OEM Options

NewsJun.10,2025

-

20x20x2 Air Filter High-Efficiency Dust Filtration for Clean Air

NewsJun.10,2025