Jun . 13, 2024 11:11 Back to list

Highly acclaimed stainless steel filter mesh

The Pivotal Role of Famous Stainless Steel Filtration Mesh in Modern Industries

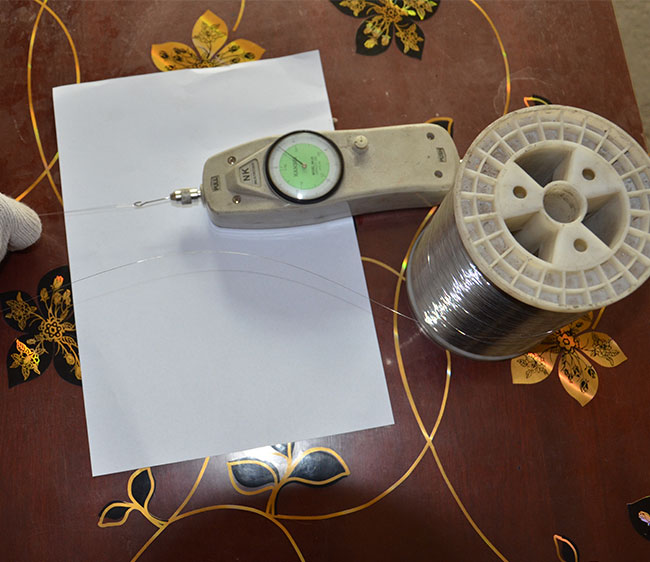

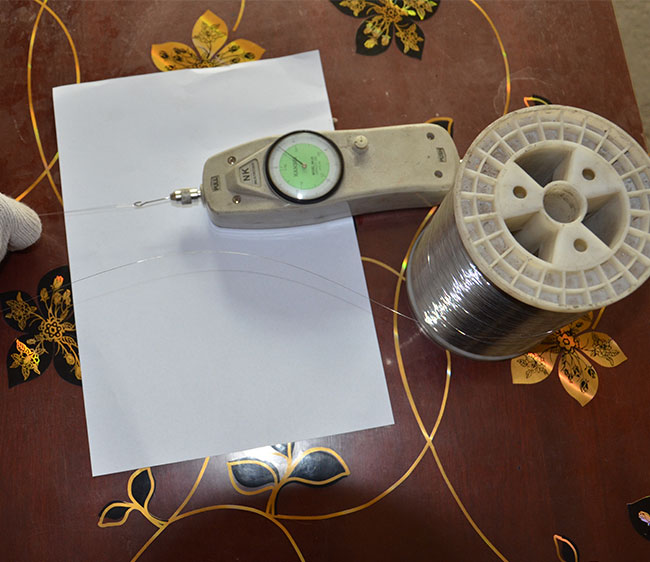

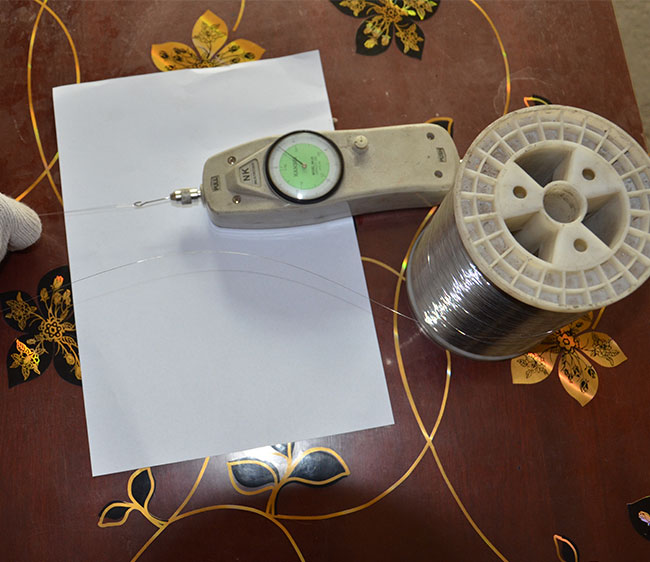

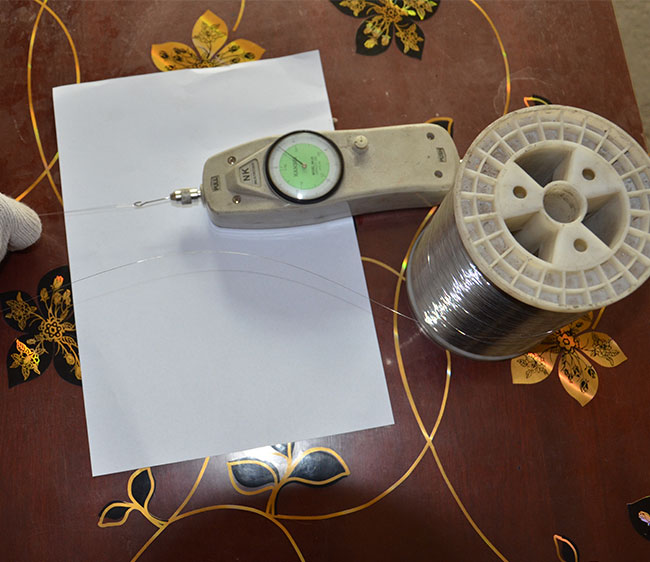

In the realm of industrial processes and engineering applications, a material that consistently stands out for its durability and performance is the famous stainless steel filtration mesh. This innovative technology has revolutionized filtration systems across various sectors, from chemical processing to food and beverage industries, and even in environmental protection.

Stainless steel filtration mesh, as the name suggests, is a woven wire mesh made primarily from stainless steel alloy. Its fame lies in its exceptional properties - resistance to corrosion, high temperature tolerance, strength, and longevity. These characteristics make it an ideal choice for applications where robustness and precision filtration are paramount.

The manufacturing process of stainless steel filtration mesh involves weaving wires together to form a grid-like structure with uniform. The size and density of these pores can be meticulously controlled, allowing for the filtration of particles of varying sizes. This versatility makes it adaptable to different industrial needs, from fine particle separation to coarse screening.

One of the key areas where stainless steel filtration mesh shines is in chemical processing. It is used in reactors, distillation columns, and separation equipment due to its resistance to harsh chemicals and high temperatures. In the oil and gas industry, it serves as a critical component in drilling operations, ensuring the removal of contaminants and maintaining fluid purity.

In the food and beverage sector, hygiene is of utmost importance

In the food and beverage sector, hygiene is of utmost importance In the food and beverage sector, hygiene is of utmost importance

In the food and beverage sector, hygiene is of utmost importance

In the food and beverage sector, hygiene is of utmost importance

In the food and beverage sector, hygiene is of utmost importance famous stainless steel filtration mesh. The non-corrosive nature of stainless steel and its ability to withstand repeated cleaning and sanitization cycles make it a go-to choice for filtration in processes like brewing, bottling, and refining. Similarly, in pharmaceuticals, it ensures the purity of medications by filtering out impurities.

Moreover, the environmental sector benefits from stainless steel filtration mesh in wastewater treatment plants, air pollution control devices, and even in solar energy applications. Its durability helps to reduce maintenance costs and increase operational efficiency.

The global market for stainless steel filtration mesh is a testament to its significance. Renowned manufacturers continually invest in research and development to improve mesh quality, weave patterns, and corrosion resistance. They cater to diverse industries, providing customized solutions to meet specific filtration requirements.

In conclusion, the famous stainless steel filtration mesh is more than just a filtration tool; it's a technological breakthrough that has transformed the way we approach filtration challenges. Its enduring popularity is a result of its unique combination of strength, durability, and adaptability. As industries continue to evolve, so will the role of this remarkable material, ensuring clean, efficient, and safe processes in countless applications.

famous stainless steel filtration mesh. The non-corrosive nature of stainless steel and its ability to withstand repeated cleaning and sanitization cycles make it a go-to choice for filtration in processes like brewing, bottling, and refining. Similarly, in pharmaceuticals, it ensures the purity of medications by filtering out impurities.

Moreover, the environmental sector benefits from stainless steel filtration mesh in wastewater treatment plants, air pollution control devices, and even in solar energy applications. Its durability helps to reduce maintenance costs and increase operational efficiency.

The global market for stainless steel filtration mesh is a testament to its significance. Renowned manufacturers continually invest in research and development to improve mesh quality, weave patterns, and corrosion resistance. They cater to diverse industries, providing customized solutions to meet specific filtration requirements.

In conclusion, the famous stainless steel filtration mesh is more than just a filtration tool; it's a technological breakthrough that has transformed the way we approach filtration challenges. Its enduring popularity is a result of its unique combination of strength, durability, and adaptability. As industries continue to evolve, so will the role of this remarkable material, ensuring clean, efficient, and safe processes in countless applications.

In the food and beverage sector, hygiene is of utmost importance

In the food and beverage sector, hygiene is of utmost importance

In the food and beverage sector, hygiene is of utmost importance

In the food and beverage sector, hygiene is of utmost importance famous stainless steel filtration mesh. The non-corrosive nature of stainless steel and its ability to withstand repeated cleaning and sanitization cycles make it a go-to choice for filtration in processes like brewing, bottling, and refining. Similarly, in pharmaceuticals, it ensures the purity of medications by filtering out impurities.

Moreover, the environmental sector benefits from stainless steel filtration mesh in wastewater treatment plants, air pollution control devices, and even in solar energy applications. Its durability helps to reduce maintenance costs and increase operational efficiency.

The global market for stainless steel filtration mesh is a testament to its significance. Renowned manufacturers continually invest in research and development to improve mesh quality, weave patterns, and corrosion resistance. They cater to diverse industries, providing customized solutions to meet specific filtration requirements.

In conclusion, the famous stainless steel filtration mesh is more than just a filtration tool; it's a technological breakthrough that has transformed the way we approach filtration challenges. Its enduring popularity is a result of its unique combination of strength, durability, and adaptability. As industries continue to evolve, so will the role of this remarkable material, ensuring clean, efficient, and safe processes in countless applications.

famous stainless steel filtration mesh. The non-corrosive nature of stainless steel and its ability to withstand repeated cleaning and sanitization cycles make it a go-to choice for filtration in processes like brewing, bottling, and refining. Similarly, in pharmaceuticals, it ensures the purity of medications by filtering out impurities.

Moreover, the environmental sector benefits from stainless steel filtration mesh in wastewater treatment plants, air pollution control devices, and even in solar energy applications. Its durability helps to reduce maintenance costs and increase operational efficiency.

The global market for stainless steel filtration mesh is a testament to its significance. Renowned manufacturers continually invest in research and development to improve mesh quality, weave patterns, and corrosion resistance. They cater to diverse industries, providing customized solutions to meet specific filtration requirements.

In conclusion, the famous stainless steel filtration mesh is more than just a filtration tool; it's a technological breakthrough that has transformed the way we approach filtration challenges. Its enduring popularity is a result of its unique combination of strength, durability, and adaptability. As industries continue to evolve, so will the role of this remarkable material, ensuring clean, efficient, and safe processes in countless applications. share

Latest news

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025