Dec . 10, 2024 18:07 Back to list

high quality wire cloth manufacturing

High-Quality Wire Cloth Manufacturing Ensuring Excellence in Material Production

In the realm of industrial applications, wire cloth, also known as wire mesh, plays a pivotal role across various sectors, such as construction, filtration, automotive, and many more. The demand for high-quality wire cloth has surged as industries strive for better efficiency, precision, and durability in their processes. This article delves into the essential aspects of high-quality wire cloth manufacturing, focusing on the materials, processes, and quality controls that define excellence in this field.

Understanding Wire Cloth

Wire cloth is essentially a woven mesh made from metal wires. It is available in a variety of materials, including stainless steel, galvanized steel, brass, and copper, each chosen for their unique properties. The wire cloth is characterized by its mesh size, aperture, and the diameter of the wire used, which can all be customized according to specific needs. Applications range from use in construction as reinforcing material to filtration solutions in petrochemical industries.

Raw Materials The Foundation of Quality

The quality of wire cloth is intrinsically linked to the materials used in its production. Stainless steel is often the preferred choice due to its corrosion resistance, mechanical strength, and longevity. When selecting materials, manufacturers must consider factors such as tensile strength, ductility, and the environment in which the wire cloth will be used. For example, wire cloth exposed to harsh chemicals or extreme conditions necessitates materials that withstand such challenges.

Other elements such as the wire drawing process—which involves pulling the raw metal into finer wires—are critical in ensuring high-quality output. The consistency in wire diameter is essential; variance can lead to structural weaknesses in the final product.

Manufacturing Process Precision and Efficiency

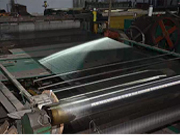

The manufacturing process of wire cloth involves several stages, from wire drawing to weaving and finally finishing. Each step requires precision and high-quality machinery to ensure that the final product meets stringent standards.

high quality wire cloth manufacturing

1. Wire Drawing This is the initial stage where metal rods are drawn into wires of specific diameters. Advanced technology, such as computerized wire drawing machines, allows for greater accuracy and consistency in wire thickness and tensile strength.

2. Weaving The drawn wires are then woven into layers to create the mesh. Various weaving techniques, such as plain weave, twill weave, or Dutch weave, can be employed depending on the specific application requirements. Automated weaving machines help achieve high production rates while minimizing human error.

3. Finishing After weaving, the wire cloth undergoes finishing processes which may include cutting, edging, and coating. Powder coating or galvanization can enhance corrosion resistance and aesthetic appeal. Quality control measures at this stage are critical. Any defects, such as improperly woven patterns or inadequate finishing, must be addressed.

Quality Control Ensuring Excellence

Quality control is an integral part of high-quality wire cloth manufacturing. Manufacturers implement stringent testing protocols at each stage of production. This can include

- Tensile Strength Testing Ensuring that the wire can withstand the required loads without failure. - Aperture Size Verification Measuring the openings in the wire mesh to confirm they meet specifications for filtration or containment applications. - Surface Integrity Checks Inspecting the surface finish for any defects or irregularities that could affect performance.

Additionally, third-party quality inspections are often employed, providing an unbiased assessment of product quality. Certification to standards such as ISO 9001 ensures that manufacturers adhere to international quality management principles, promoting continual improvement and customer satisfaction.

Conclusion

High-quality wire cloth manufacturing is a complex process that requires meticulous attention to detail at every step, from material selection to production and quality control. As industries continue to evolve and demand more from their suppliers, manufacturers who prioritize quality, innovation, and efficiency will thrive. By investing in superior materials, embracing modern technology, and committing to rigorous quality checks, wire cloth manufacturers can ensure that their products not only meet but exceed industry standards, fulfilling the critical roles they play across various applications. As we witness advancements in manufacturing technology and materials science, the future of wire cloth manufacturing looks promising, paving the way for enhanced performance and durability in the years to come.

share

-

CE Certified 250 Micron Stainless Steel Mesh | Precision & Durability

NewsAug.27,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.26,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision & Durability

NewsAug.25,2025

-

Premium CE Certified Metal Fine Mesh for Precision & Safety

NewsAug.24,2025

-

Stainless Steel Wedge Wire Mesh: Durable, Precision Filtration

NewsAug.23,2025

-

CE Certified 250 Micron Stainless Steel Mesh for Precision Filtration

NewsAug.22,2025