Jul . 26, 2024 09:20 Back to list

Innovative Hexagonal Wire Netting Machine for Enhanced Durability and Efficiency in Production

The Famous Hexagonal Wire Netting Machine A Revolutionary Tool for Various Industries

In the ever-evolving world of industrial machinery, the hexagonal wire netting machine stands out as a beacon of innovation and efficiency. This remarkable device has transformed the production of hexagonal wire mesh, widely used across multiple sectors, including agriculture, construction, and fencing. With its advanced technology and versatility, this machine has become indispensable for manufacturers around the globe.

Understanding Hexagonal Wire Netting

Before diving into the intricacies of the machine itself, it is essential to comprehend what hexagonal wire netting is. Hexagonal wire mesh, often referred to as rabbit wire or chicken wire, is made from durable steel or galvanized iron wire, which is twisted into a hexagonal pattern. This type of netting is known for its strength and durability, making it suitable for various applications. It's particularly popular in agriculture to create enclosures for animals, support climbing plants, and secure gardens from pests. Moreover, it is extensively used in construction to provide safety barriers and for landscaping purposes.

The Functionality of the Hexagonal Wire Netting Machine

The hexagonal wire netting machine automates the process of weaving wire into the desired hexagonal shape, which significantly boosts productivity. Traditional methods of manufacturing wire mesh are labor-intensive and time-consuming, often resulting in inconsistencies in quality. However, with modern machines, these issues are largely mitigated.

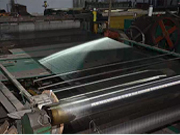

A typical hexagonal wire netting machine operates by feeding wire into a series of rollers that twist and weave the wire together to form hexagonal meshes. The machinery allows for precise adjustments in the size of the hexagons, the thickness of the wire, and the overall dimensions of the finished product. This level of customization makes it suitable for a wide range of applications, from small-scale garden projects to large industrial needs.

Benefits of Using Hexagonal Wire Netting Machines

famous hexagonal wire netting machine

1. Efficiency One of the most significant advantages of using a hexagonal wire netting machine is its efficiency. These machines can produce large quantities of wire mesh in a fraction of the time it would take to manufacture manually. This efficiency is essential for meeting market demands and reducing production costs.

2. Quality Control With automated processes, manufacturers can maintain a consistent quality in their products. The machine’s settings can be calibrated to ensure that each piece of wire mesh meets specific standards, reducing the likelihood of defects.

3. Versatility The ability to customize product specifications makes hexagonal wire netting machines ideal for various industries. Whether the requirement is for different wire diameters, mesh sizes, or roll lengths, the machine can be adjusted to meet these varying needs.

4. Labor Savings Automation reduces the need for extensive manual labor, allowing companies to allocate their workforce to other critical tasks. This not only saves labor costs but also enhances workplace safety by minimizing manual handling of heavy and potentially hazardous materials.

The Future of Hexagonal Wire Netting Machines

As industries continue to evolve and embrace technology, the hexagonal wire netting machine is likely to see further advancements. Integration with automation and smart technology can enhance its functionality, enabling real-time monitoring and adjustments during the production process. Innovations such as AI and machine learning may also play a role in optimizing designs and production schedules based on market trends and demands.

Conclusion

The famous hexagonal wire netting machine is more than just a tool; it is a crucial player in various industries, fostering growth and ensuring quality. Its efficiency, versatility, and ability to produce high-quality products have secured its place as an essential machinery in wire mesh manufacturing. As technology continues to advance, we can expect even greater innovations in this domain, further solidifying the machine’s importance and relevance in the future.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025