Aug . 01, 2024 07:36 Back to list

Innovative High-Quality Wire Netting Machine for Efficient Production and Durable Mesh Solutions

The Importance of High-Quality Wire Net Machines in Modern Manufacturing

In the rapidly evolving landscape of manufacturing and production, the demand for high-quality machinery has never been more critical. One such essential machine is the high-quality wire net machine, which plays a pivotal role in producing wire mesh and netting used in a variety of industries. From construction to agriculture, the applications of wire netting are vast and diverse, making the reliability and efficiency of the machines that produce them a top priority.

The Importance of High-Quality Wire Net Machines in Modern Manufacturing

One of the key features of high-quality wire net machines is their precision engineering. These machines utilize advanced technology to ensure that every piece of wire is woven or welded accurately, forming a strong and durable net. The precision of the machine not only affects the quality of the final product but also impacts the overall safety and reliability of the structures or systems that utilize the wire mesh. For example, in construction, high-quality wire mesh is essential for reinforcing concrete and ensuring the longevity of buildings and infrastructure.

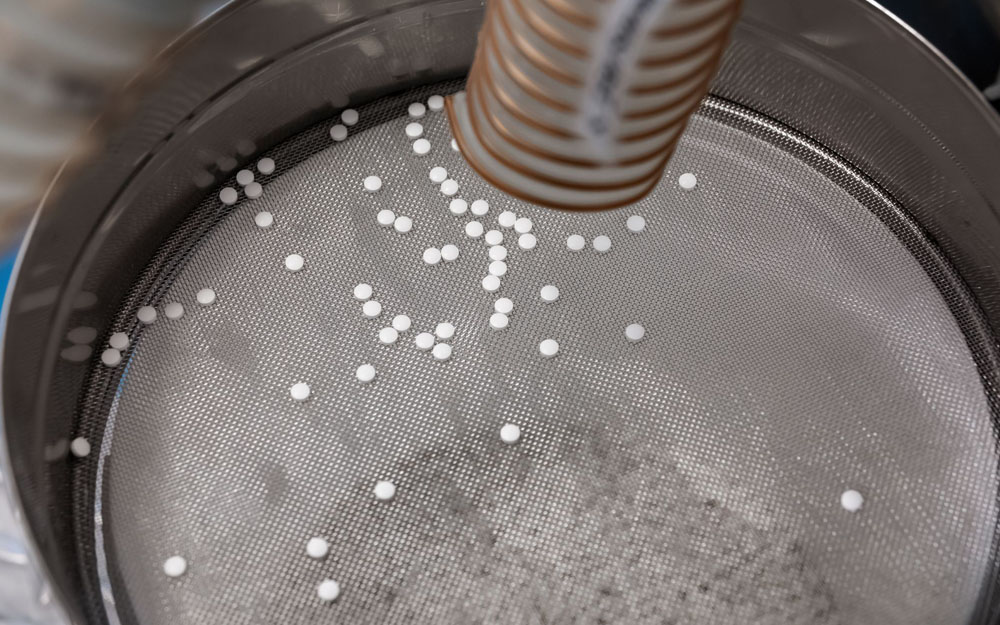

high quality wire net machine

Moreover, high-quality wire net machines are equipped with advanced control systems that enhance their functionality. Features such as programmable logic controllers (PLCs) allow for automated operation, reducing the need for manual intervention and minimizing the risk of human error. This automation leads to increased productivity, as manufacturers can produce larger quantities of wire netting within a shorter time frame. Additionally, modern wire net machines often include user-friendly interfaces that make it easier for operators to monitor and control the production process.

Efficiency is another crucial aspect of high-quality wire net machines. These machines are designed to operate smoothly and reduce waste, making them not only economical but also environmentally friendly. By optimizing material usage and minimizing scrap, manufacturers can significantly lower production costs while contributing to sustainability efforts. This focus on efficiency aligns with the broader goals of many industries to reduce waste and promote eco-friendly practices.

Maintenance is also an essential consideration when it comes to high-quality wire net machines. Regular upkeep ensures that these machines continue to operate at peak performance levels. Manufacturers that invest in high-quality machinery benefit from lower maintenance costs and longer machine lifespans. This durability translates into better return on investment, as businesses need to replace machinery less frequently.

In conclusion, the significance of high-quality wire net machines cannot be overstated. They are vital in producing wire mesh that meets the diverse needs of various industries. With their precision engineering, advanced technology, efficiency, and durability, these machines not only enhance productivity but also ensure the safety and reliability of the final products. As the manufacturing sector continues to evolve, the demand for innovative and high-quality machinery like wire net machines will only increase, driving advancements that support both industrial growth and sustainability initiatives. Investing in such technology is not just a smart business move; it's a commitment to quality and excellence in manufacturing.

share

-

CE Certified 250 Micron SS Mesh: Precision & Durability

NewsAug.15,2025

-

CE Certified 250 Micron Stainless Steel Mesh - Durable & Precise

NewsAug.14,2025

-

Precision CE Certified 250 Micron Stainless Steel Mesh

NewsAug.13,2025

-

CE Certified Metal Fine Mesh & Screen Fabric | Top Quality

NewsAug.12,2025

-

Premium CE Certified 250 Micron Stainless Steel Mesh

NewsAug.11,2025

-

CE Certified Stainless Steel Wire Mesh for Screen Printing

NewsAug.10,2025